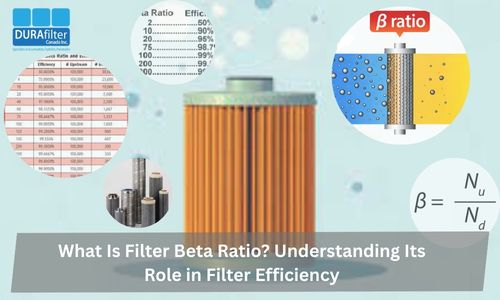

Modern hydraulic, lubrication and industrial fluid systems rely heavily on effective filtration to ensure smooth operation and long equipment life. Contamination in fluids such as metal particles, dust or fibers can cause excessive wear, reduced performance and unexpected failures. This is where the beta ratio filter concept becomes essential. Understanding how a beta ratio of filter works allows engineers, maintenance teams and buyers to make informed decisions that directly affect system reliability, operating cost and overall Filter Efficiency.

What Is Filter Beta Ratio?

The beta rating filter is a standardized way to express how efficiently a filter removes particles of a specific size from a fluid. In simple terms, it compares the number of particles present before filtration to the number that remain after filtration at a defined micron size. The higher the beta value, the better the filter’s ability to trap contaminants.

A beta ratio filter does not just say that a filter is “good” or “fine.” Instead, it quantifies performance in measurable terms. For example, when evaluating Filter Beta Ratios, you can clearly see how effective one filter is compared to another under the same test conditions. This clarity is critical in systems where even small particles can damage components.

From a practical perspective, the beta ratio of filter directly influences equipment lifespan. Higher-rated filters reduce abrasive wear, maintain oil cleanliness and help systems operate within design tolerances. Over time, this improves Filter Efficiency and reduces the frequency of repairs or oil replacement.

How to Calculate Beta Ratio of Filter?

The calculation behind a beta rating filter is straightforward but powerful. It is based on particle counts measured upstream (before the filter) and downstream (after the filter) for a specific particle size.

Beta Ratio (β) = Number of particles upstream ÷ Number of particles downstream

This formula shows how many particles are removed by the filter. For instance, if there are 1,000 particles upstream and 10 downstream, the beta ratio of filter is 100. That means only one out of every 100 particles of that size passes through the filter.

This calculation forms the foundation of Beta Ratio Filtration testing. Standardized tests, such as those defined in ISO 16889, ensure consistency when manufacturers publish Filter Beta Ratios. Without standardized testing, comparing different filters would be unreliable and misleading.

In oil and hydraulic applications, Oil Filter Beta Ratios are especially important because fluid cleanliness directly affects valves, pumps and bearings. Accurate beta calculations help ensure that the selected filter meets system cleanliness requirements.

Why Beta Ratio Matters in Filtration Systems

Filter Beta Ratios are not just numbers they reflect the real-world ability of a filter to protect machinery. Using a filter with inadequate beta rating filter can lead to fluid contamination, accelerated wear of moving parts and unexpected system downtime. Understanding Beta Ratings of Liquid Filters is crucial for:

- Selecting the right filter for the application

- Maintaining clean hydraulic or lubricating oil

- Reducing maintenance costs

- Ensuring long-term Beta Stability in filter element

A properly chosen filter ensures consistent Filter Efficiency, minimizes contamination and enhances fluid life. For example, in high-pressure hydraulic systems, even small particles can cause severe damage if a low beta ratio of filter is used.

Absolute Filter Rating and Nominal Filter Rating

Filter ratings are often described as absolute or nominal and understanding the difference is essential when interpreting Beta Ratings of Liquid Filters. A nominal rating generally indicates that a filter removes a certain percentage of particles at a given size, but the exact efficiency can vary. In contrast, an absolute rating implies a much higher and more consistent level of particle removal.

Absolute ratings are typically derived from standardized Beta Ratio Filtration tests. These tests show near-complete particle capture at the stated micron size. As a result, absolute-rated filters usually have higher Filter Beta Ratios and offer superior protection.

Nominal ratings, while useful in less critical applications, may not provide enough detail for systems where contamination control is vital. This is why many industries prefer Oil Filter Beta Ratios that are clearly defined and supported by ISO testing data.

Understanding these distinctions helps users select the right beta rating filter for their specific application, balancing cost, performance and risk.

Common Filter Beta Ratio Ratings Explained

Different Filter Beta Ratios indicate different levels of filtration performance. A higher beta value always means fewer particles pass through the filter at the tested size. For example, a beta ratio of 10 corresponds to about 90% particle removal, while a beta ratio of 200 corresponds to 99.5% removal.

The table below illustrates how typical beta values relate to filtration efficiency:

| Beta Ratio (β) | Particle Removal Efficiency | Typical Application |

| β = 2 | 50% | Low-risk systems |

| β = 10 | 90% | General hydraulics |

| β = 75 | 98.7% | Industrial systems |

| β = 200 | 99.5% | Precision equipment |

These values make it easier to compare Beta Ratings of Liquid Filters across manufacturers. When reviewing specifications, always look for the particle size at which the beta ratio of filter is measured, as performance can vary significantly with micron rating.

In lubrication systems, Oil Filter Beta Ratios with higher values are often chosen to protect sensitive bearings and gears. This ensures stable oil cleanliness and long-term Filter Efficiency.

The Importance of Filter Beta Ratio in Lubricating Systems

Lubricating systems are particularly sensitive to contamination because oil circulates continuously through critical components. Even small particles can cause surface fatigue, scoring or increased friction. Selecting the correct beta rating filter is therefore essential.

A well-chosen beta ratio filter ensures that contaminants are removed before they reach wear-prone areas. This not only extends component life but also maintains consistent oil properties. Clean oil reduces oxidation, maintains viscosity and supports efficient heat transfer.

Key benefits include:

- Reduced wear and tear – Clean oil minimizes abrasive damage.

- Improved fluid life – Lower contamination levels extend oil replacement intervals.

- Lower maintenance costs – Fewer breakdowns reduce unplanned repairs.

- Enhanced Beta Stability in filter element – Stable Beta Ratio Filtration ensures long-term reliability.

Another major benefit is cost reduction. With proper Oil Filter Beta Ratios, oil change intervals can be optimized and unexpected failures are minimized. Over time, the improved Filter Efficiency translates into lower maintenance expenses and higher equipment availability.

Long-term reliability also depends on Beta Stability in filter element. Filters that maintain their Filter Beta Ratios throughout their service life provide dependable protection even under varying flow rates and pressure conditions.

Beta Stability and Long-Term Performance

While a filter’s initial efficiency is important, its ability to perform consistently over time is what truly determines its value. Beta Stability in filter element describes how well a filter maintains its rated beta value throughout its service life, even as contaminants build up inside the media.

Filters with poor stability may deliver high Filter Beta Ratios when they are new, but their efficiency can decline as differential pressure rises. This gradual loss of performance can weaken Beta Ratio Filtration effectiveness and allow harmful particles to circulate through the system, increasing wear and the risk of component failure.

Long-term Filter Efficiency depends heavily on filter design and construction quality. Advanced media technology, strong structural support, and optimized pleat geometry help ensure that the filter continues to perform as expected under real operating conditions, including those found in Industrial Hydraulic Filters.

Key factors that support beta stability include:

- Use of high-quality filter media that resists deformation

- Robust pleat design to handle contaminant loading evenly

- Strong end caps and bonding to prevent bypass or collapse

- Consistent flow characteristics that limit pressure spikes

When assessing Beta Ratings of Liquid Filters, it is essential to look beyond the initial rating. A filter that sustains its performance over time provides better protection, longer service intervals, and improved system reliability.

Choosing the Right Filter Based on Beta Ratio

Selecting the right beta ratio of filter requires understanding system requirements, operating conditions and contamination sensitivity. High-pressure hydraulic systems, for example, often require higher Filter Beta Ratios than low-pressure applications.

It is also important to balance filtration performance with flow requirements. Extremely high beta rating filter values may increase pressure drop if the filter is undersized. Therefore, proper sizing and application-specific design are essential to maintain optimal Filter Efficiency.

When comparing options, always rely on verified Oil Filter Beta Ratios and standardized test data. This ensures that the selected filter delivers the expected level of protection in real-world conditions.

Conclusion

The beta ratio filter is one of the most important metrics in modern filtration technology. It provides a clear, measurable way to evaluate how effectively a filter removes contaminants and protects equipment. By understanding the beta ratio of filter, users can make informed decisions that improve reliability, reduce wear and lower operating costs.

From hydraulic systems to lubrication circuits, Beta Ratio Filtration plays a critical role in maintaining fluid cleanliness. High Filter Beta Ratios, supported by strong Beta Stability in filter element, ensure consistent Filter Efficiency over time. Selecting filters based on proven Oil Filter Beta Ratios and verified Beta Ratings of Liquid Filters ultimately leads to longer equipment life, fewer failures and better overall system performance.