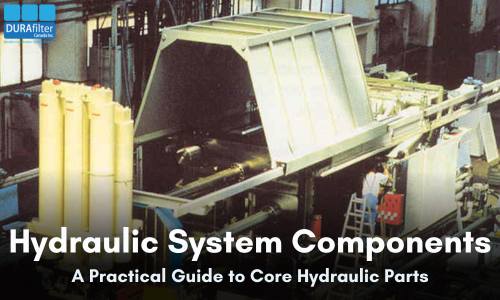

If you work with heavy machinery, construction equipment, or industrial systems, you already know hydraulics power some of the toughest jobs out there. But when something goes wrong, understanding the basic components of a hydraulic system can mean the difference between a quick fix and days of downtime.

After three decades of working with hydraulic equipment across North America, we’ve seen every type of failure imaginable. Most problems trace back to one of the core hydraulic system parts not doing its job properly. This guide breaks down what each component does and how they work together to keep your equipment running.

What Are Hydraulic System Components?

What Are Hydraulic System Components?

Hydraulic components are the individual parts that work together to convert fluid power into mechanical force. Think of a hydraulic system like your home’s plumbing, except instead of just moving water, it’s generating tremendous force to lift, push, pull, or rotate heavy loads.

The basic parts of hydraulic system include elements that generate pressure, control flow, transmit power, and condition the fluid. Each piece plays a specific role, and when one fails, the entire system can shut down.

The Main Parts of Hydraulic System

Let’s walk through the fundamental hydraulic system parts you’ll find in most industrial equipment.

-

Hydraulic Reservoir

The reservoir is where everything starts. This tank stores hydraulic fluid when it’s not being used and gives the fluid time to cool down, release air bubbles, and allow contaminants to settle out.

What it does:

- Stores hydraulic oil safely

- Allows air to escape from the fluid

- Helps dissipate heat

- Provides a place for contaminants to settle

You’ll find reservoirs in all sizes, from small 5-gallon tanks on compact equipment to massive 500-gallon units on industrial machines. The reservoir needs to be large enough to handle fluid expansion from heat and keep the pump supplied during operation.

Common issues: Low fluid levels, contamination from dirty breathers, and internal baffles that break loose cause most reservoir problems.

-

Hydraulic Pump

If the reservoir is where fluid lives, the pump is what puts it to work. The pump is the heart of any hydraulic system, converting mechanical energy from a motor or engine into hydraulic pressure.

Types you’ll encounter:

- Gear pumps (simple and reliable for basic applications)

- Vane pumps (quieter operation, good for medium pressures)

- Piston pumps (highest pressures, most efficient)

The hydraulic pump creates flow, not pressure. Pressure only develops when that flow meets resistance, like when you’re trying to lift a load or push against something. This is an important distinction that many people get wrong.

What goes wrong: Pumps fail from contaminated fluid, running dry, cavitation from restricted inlet lines, or simply wearing out from years of use.

-

Hydraulic Actuators

Actuators are where hydraulic pressure becomes useful work. These components in a hydraulic system convert fluid power back into mechanical motion.

- Hydraulic Cylinders: These create linear motion, pushing and pulling in straight lines. You see them lifting dump truck beds, extending excavator arms, and operating press machines. Cylinders come in single-acting (pressure on one side only) or double-acting (pressure on both sides for push and pull).

- Hydraulic Motors: These create rotary motion to drive wheels, rotate drums, or spin augers. Unlike cylinders that move back and forth, motors spin continuously like an electric motor would.

Real-world example: On a backhoe, cylinders extend the boom and bucket, while a hydraulic motor might drive the swing mechanism that rotates the cab.

-

Control Valves

Valves are the brain of your hydraulic circuit. These hydraulic components control where fluid goes, how fast it moves, and at what pressure. Without hydraulic valves, you’d have no way to direct the power to where you need it.

- Directional Control Valves: These decide which way the fluid flows, forward or reverse, up or down. When you move a joystick on a loader, you’re operating a directional valve.

- Pressure Control Valves: These protect your system by limiting maximum pressure. Relief valves are the most common type, opening when pressure gets too high to prevent damage.

- Flow Control Valves: These regulate how fast actuators move by controlling fluid volume. They’re crucial for synchronized motion and precise speed control.

The components of hydraulic circuit work together through valve configurations. A simple system might have one valve, while complex machines use valve banks with dozens of sections.

-

Hydraulic Filters

Contamination destroys hydraulic systems faster than anything else. Filters are your defense against wear particles, dirt, and debris that would otherwise damage pumps, valves, and cylinders.

Where filters work:

- Suction side (protecting the pump)

- Pressure side (protecting sensitive valves)

- Return line (catching wear particles before they reach the reservoir)

Modern hydraulic filters can capture particles as small as 3 microns, that’s smaller than a human hair by far. Regular filter changes are the cheapest insurance you can buy for hydraulic equipment.

Pro tip: Always use quality replacement filters that meet original equipment specifications. Bargain filters often use inferior media that either restricts flow or lets contaminants through.

-

Hydraulic Fluid

Often overlooked, the fluid itself is one of the basic hydraulic components. It’s not just oil, it’s a carefully formulated lubricant that transmits power, lubricates moving parts, seals clearances, and removes heat.

What hydraulic fluid does:

- Transfers power from pump to actuators

- Lubricates all internal components

- Seals gaps in pumps and valves

- Carries away heat and contaminants

- Protects against rust and corrosion

The wrong fluid or contaminated oil causes more failures than most people realize. Water contamination, oxidation, and additive depletion silently damage systems over time.

Know More About: Hydraulic Fluid vs Hydraulic Oil

-

Hydraulic Hoses and Fittings

These hydraulic system parts connect everything together, carrying high-pressure fluid throughout the system. Hoses need to handle pressure, flexing, abrasion, and temperature extremes.

Types of lines:

- Rigid steel tubing (permanent installations)

- Flexible hoses (where movement is required)

- Thermoplastic hoses (lighter weight applications)

Fittings seem simple but choosing the wrong type or improper installation causes leaks, pressure losses, and contamination entry. Common fitting types include JIC, NPT, SAE, and metric standards.

Warning signs: Bulging hoses, visible wear, leaks at fittings, or hoses that feel hard indicate replacement is needed before failure occurs.

-

Hydraulic Accumulators

Hydraulic accumulators store pressurized fluid for later use. Think of them as pressure batteries, they charge up when the system has extra capacity and discharge when you need a quick burst of power.

Common uses:

- Emergency backup power

- Shock absorption

- Maintaining pressure during pump off cycles

- Compensating for leakage

- Energy savings in cyclic operations

At DURAfilter, we’re the exclusive distributors for Bolenz & Schafer and EPE Italiana accumulator systems. We’ve seen how properly sized accumulators improve system response and efficiency while reducing energy consumption.

How Basic Components of a Hydraulic System Work Together

Understanding individual hydraulic components and functions is one thing, but seeing how they interact gives you the complete picture.

The basic cycle works like this:

- The pump draws fluid from the reservoir and creates flow

- Fluid travels through filters that remove contaminants

- Pressure builds when flow meets resistance at a valve or actuator

- Control valves direct fluid to the desired actuator

- The actuator (cylinder or motor) performs work

- Return fluid flows back through filters to the reservoir

- The cycle repeats continuously during operation

Accumulators, pressure switches, sensors, and gauges monitor and modify this flow based on system requirements. More complex systems add proportional valves, servo controls, and electronic management, but the fundamental components remain the same.

Choosing Quality Hydraulic System Parts

Not all components in a hydraulic system are created equal. We regularly see equipment owners struggle with failures from substandard parts that seemed like a good deal initially.

What separates quality components:

- Engineering standards: Reputable manufacturers follow strict industry standards like ISO, SAE, and NFPA specifications. These ensure parts will perform as expected under rated conditions.

- Material quality: Genuine components use proper metallurgy, seals, and coatings. Knockoffs often substitute inferior materials that fail prematurely.

- Testing and certification: Quality parts undergo rigorous testing for pressure cycles, temperature ranges, and contamination resistance. Documentation proves they meet specifications.

- Manufacturer support: Established brands provide technical data, application support, and warranty backing. You’re not left guessing about proper installation or troubleshooting.

At DURAfilter, we partner with respected European hydraulic manufacturers like Marzocchi, Berarma, Rexroth Bosch, and PONAR Wadowice. These brands have proven themselves in demanding applications worldwide.

Common Problems with Hydraulic Components

Knowing what typically fails helps you spot trouble early:

- Contamination damage: Shows up as scoring on cylinder rods, stuck valve spools, and rapid pump wear. The solution is better filtration and cleaner fluid handling.

- Seal failures: Leaking cylinders, dripping fittings, and weeping pump shafts indicate seal problems from age, contamination, or incompatible fluids.

- Cavitation: Air bubbles in the fluid cause noise, erratic operation, and component damage. Usually stems from low reservoir levels, restricted inlet lines, or pump problems.

- Overheating: High temperatures break down fluid and damage seals. Check for undersized reservoirs, continuous relief valve bypass, or insufficient cooling.

- Pressure loss: Weak or slow actuators point to internal leakage in pumps, valves, or cylinders. Worn components no longer maintain pressure effectively.

Maintaining Your Hydraulic System Components

Prevention beats repair every time. These practices keep basic parts of hydraulic system working properly:

- Check fluid levels daily: Low fluid leads to pump damage and air entrainment. Top off with the correct fluid type.

- Change filters on schedule: Don’t wait for bypass indicators. Proactive changes prevent contamination damage.

- Monitor for leaks: External leaks waste fluid and invite contamination. Internal leaks rob power and generate heat.

- Test fluid regularly: Oil analysis reveals problems before they cause failures. Check for water, particles, viscosity changes, and additive depletion.

- Inspect hoses and fittings: Look for wear, damage, and proper routing. Replace suspect hoses before they burst.

- Keep systems clean: Wipe down components, protect openings during service, and use proper fluid handling practices.

- Document everything: Track maintenance, fluid changes, and component replacements. Patterns reveal systemic issues.

When to Replace Hydraulic Components

Some parts wear gradually while others fail suddenly. Understanding component life expectancy helps you plan maintenance:

- Filters and fluid: Replace on schedule or when analysis indicates degradation. Don’t stretch intervals to save money, it costs more in the long run.

- Hoses: Typically 3-5 years depending on application. Replace if you see signs of wear before failure occurs.

- Seals: As needed when leaks develop. Keep spares for critical equipment.

- Pumps and motors: Major repairs or replacement when efficiency drops significantly or internal wear becomes excessive.

- Valves: Rebuild or replace when they stick, leak internally, or don’t shift properly.

- Cylinders: Reseal when leaking, replace if barrels are scored or bent.

Expert Support for Your Hydraulic Needs

Understanding hydraulic system components is valuable, but having a trusted partner makes the difference when you need parts, service, or technical guidance.

DURAfilter has supplied hydraulic components across diverse industries from past three decades. We help customers in industries including agriculture, construction, automotive, logistics, and oil & gas maintain their critical equipment.

Our team provides more than parts, we offer application expertise, technical support for troubleshooting, and quality components from manufacturers we trust. Whether you need a replacement filter element, accumulator system, pump, or valve, we ensure you get the right component for your specific application.

Need help identifying hydraulic system parts or sourcing quality replacements?

Connect with us, our experienced team is ready to assist with your hydraulic component needs.