Hydraulic fluid contamination is the silent killer of industrial equipment, responsible for up to 75% of all hydraulic system failures. While system operators focus on obvious maintenance tasks like checking fluid levels and replacing worn components, contamination slowly but relentlessly destroys expensive hydraulic systems from within. The microscopic particles, water droplets, and chemical contaminants circulating through your hydraulic fluid are causing damage that may not become apparent until major failure occurs.

The economic impact of contamination in hydraulic systems extends far beyond component replacement costs. Unplanned downtime, reduced equipment life, increased maintenance expenses, and safety risks combine to create total costs that often exceed the original equipment investment. Understanding the sources, effects, and prevention strategies for hydraulic oil contamination enables maintenance professionals to protect their investments while maximizing equipment reliability and performance.

The guide examines the complex relationship between contamination and hydraulic system performance, while offering practical solutions that maintenance teams can implement immediately. From understanding microscopic particle behavior to implementing comprehensive contamination control strategies, we’ll explore proven methods that leading manufacturers use to protect their hydraulic investments and maintain operational excellence.

Understanding Hydraulic Fluid Contamination

Hydraulic fluid contamination encompasses any foreign substance that enters the hydraulic system and degrades performance or accelerates component wear. These contaminants range from microscopic particles invisible to the naked eye to larger debris that can cause immediate system damage. Understanding contamination types and their sources forms the foundation for effective prevention strategies.

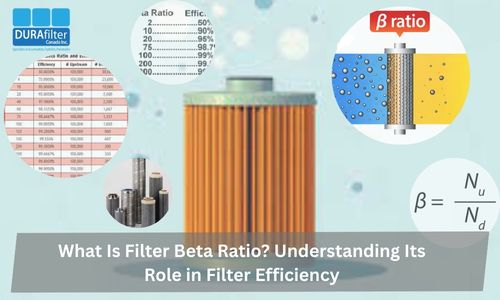

The ISO 4406 cleanliness standard provides a framework for measuring and communicating contamination levels in hydraulic systems. This standard counts particles in specific size ranges, with typical industrial systems requiring cleanliness levels between ISO 18/16/13 and ISO 16/14/11 depending on component sensitivity. Systems with servo valves or other precision components may require even stricter cleanliness standards to prevent premature failure.

Contamination measurement focuses on particles larger than 4, 6, and 14 microns because these sizes cause the most significant damage to hydraulic components. To put this in perspective, human hair measures approximately 70 microns in diameter, making the most damaging contaminants far too small to see without magnification. This invisible nature makes contamination particularly insidious, damage accumulates steadily while operators remain unaware of the problem.

Primary Sources of Hydraulic Fluid Contamination

Built-In Contamination

New hydraulic systems contain surprising amounts of contamination from manufacturing and assembly processes. Machine shops generate metal particles during component machining, while assembly operations introduce contamination through handling, welding, and installation procedures. Even new hydraulic fluid contains contamination levels that may exceed system requirements for sensitive applications.

Manufacturing tolerances in hydraulic components create clearances measured in microns, making even small amounts of built-in contamination problematic. A servo valve spool might have clearances of 2-5 microns, while manufacturing debris can easily exceed 25 microns. This size disparity explains why new systems often experience problems during initial operation if proper flushing procedures aren’t followed.

Assembly contamination includes thread sealants, cutting oils, welding slag, and debris from pipe cutting and fitting installation. Quality control procedures during manufacturing and assembly can significantly reduce built-in contamination, but complete removal is practically impossible. Effective system commissioning includes thorough flushing procedures that remove built-in contamination before it can cause component damage.

Environmental Contamination Sources

Environmental contamination enters hydraulic systems through multiple pathways, with dust and dirt representing the most common external contaminants. Construction sites, mining operations, and agricultural applications expose hydraulic systems to extreme contamination levels that can overwhelm even well-designed filtration systems.

Water contamination from environmental sources includes direct exposure to rain, washing operations, and atmospheric humidity. High-humidity environments can introduce significant water contamination even in sealed systems through condensation and vapor transmission through seals and hoses.

Temperature cycling accelerates environmental contamination ingress by creating pressure differentials that draw contaminated air into the system during cooling periods. Systems that operate in extreme temperature variations face particularly challenging contamination control requirements.

Generated Contamination

Normal system operation generates contamination through component wear, fluid breakdown, and operational processes. Even well-maintained systems produce wear particles as components operate within design parameters. Understanding normal wear patterns helps distinguish between acceptable wear and abnormal degradation indicating serious problems.

Pump wear generates metallic particles as close-clearance surfaces gradually wear during normal operation. Variable displacement pumps with complex control mechanisms typically generate more wear particles than fixed displacement pumps due to their intricate internal components and control surfaces.

Seal wear contributes both rubber particles and metallic wear from seal grooves and mating surfaces. Rubber particles can be particularly problematic because they may swell in certain fluid types, creating larger particles that cause additional problems downstream.

Filter element degradation represents another source of generated contamination. As filter media loads with contaminants, pressure differentials increase and may cause media breakdown, introducing filter fibers into the fluid stream. Quality filter elements designed for hydraulic applications resist breakdown and minimize contamination generation.

Human-Induced Contamination

Maintenance activities represent significant contamination sources if proper procedures aren’t followed. Opening hydraulic systems exposes clean fluid to atmospheric contamination, while maintenance tools and procedures can introduce additional contaminants if cleanliness protocols aren’t maintained.

Fluid handling practices significantly impact contamination levels. Transferring fluid from drums or bulk storage through contaminated hoses, funnels, or pumps can increase contamination levels far above acceptable limits. Many facilities unknowingly introduce more contamination during fluid changes than the system generates during months of operation.

Training and awareness programs help maintenance personnel understand how their actions affect system contamination levels. Simple changes in procedure can dramatically reduce contamination introduction while improving overall system reliability.

Effects of Contamination in Hydraulic Systems

Component Wear and Performance Degradation

The effects of contamination in hydraulic systems is evident primarily through accelerated component wear that reduces system efficiency and reliability. Abrasive particles act like microscopic sandpaper, gradually wearing away precision surfaces in pumps, valves, and actuators. This wear creates larger clearances that allow internal leakage, reducing system efficiency and power output.

Servo valve contamination represents one of the most serious effects of hydraulic fluid contamination. These precision components have clearances measured in microns, making them extremely sensitive to particle contamination. Contaminated servo valves exhibit erratic behavior, reduced response, and complete failure in severe cases. Replacement costs for servo valves can exceed $5,000 per unit, making contamination control economically critical.

Pump wear from contamination follows predictable patterns that maintenance professionals can learn to recognize. Internal leakage increases gradually as wear surfaces develop scratches and grooves that allow pressurized fluid to bypass working chambers. Flow output decreases while power consumption increases, reducing overall system efficiency and increasing operating costs.

Seal damage from contamination occurs through multiple mechanisms including abrasive wear, chemical attack, and thermal degradation. Contaminated seals lose their ability to prevent leakage, leading to fluid loss, safety hazards, and environmental contamination. Seal replacement often requires significant disassembly, making contamination prevention far more economical than reactive maintenance.

System Performance Issues

Contamination in hydraulic systems causes performance problems that operators notice long before component failure occurs. Erratic operation, slower cycle times, and reduced force output all indicate contamination-related problems that require immediate attention to prevent costly failures.

Flow restrictions from contamination accumulation in narrow passages reduce system capacity and efficiency. Orifices, pilot passages, and valve ports can become partially blocked by contaminant accumulation, causing unpredictable system behavior and reduced performance. These restrictions often develop gradually, making them difficult to detect until performance degradation becomes severe.

Temperature increases result from contamination-induced inefficiencies and increased friction throughout the system. Higher operating temperatures accelerate fluid breakdown and component wear, creating a cascade effect that rapidly worsens contamination problems. Effective contamination control helps maintain normal operating temperatures and extends fluid life.

Economic Impact of Hydraulic Oil Contamination

The total economic impact of hydraulic oil contamination extends far beyond obvious component replacement costs. Reduced productivity from slower cycle times, increased energy consumption from inefficient operation, and unplanned downtime from contamination-related failures create costs that often exceed the original equipment investment.

Maintenance cost increases include both planned and unplanned repairs related to contamination damage. Components that should operate reliably for thousands of hours may require replacement or overhaul after months of operation in contaminated systems. Emergency repairs during production periods often cost several times more than planned maintenance activities.

Energy efficiency losses from contamination-induced inefficiencies increase operating costs throughout the equipment lifecycle. Internal leakage, increased friction, and reduced component efficiency all contribute to higher power consumption that continues until contamination problems are resolved.

Contamination Detection and Monitoring

Fluid Analysis Programs:

- Systematic fluid analysis provides early warning of contamination problems before they cause expensive component damage. Regular sampling and testing reveal contamination trends that enable proactive maintenance and prevent fatal failures.

- Particle count testing measures contamination levels according to ISO 4406 standards, providing objective data for contamination control decisions. Automated particle counters can provide immediate results, while laboratory analysis offers more detailed information about particle composition and sources.

- Water content analysis detects moisture contamination that accelerates component wear and fluid degradation. Karl Fischer titration provides accurate water content measurement, while simpler methods like crackle testing can identify gross water contamination requiring immediate attention.

Online Monitoring Systems:

- Real-time contamination monitoring systems provide continuous feedback about system contamination levels, enabling immediate response to contamination problems. These systems integrate with existing control systems to provide alerts when contamination levels exceed acceptable limits.

- Automatic particle counters mounted permanently in hydraulic systems track contamination trends and provide early warning of developing problems. Advanced units can distinguish between different particle types and provide detailed contamination analysis without requiring fluid sampling.

- Water sensors detect moisture contamination in real-time, enabling immediate response to water ingress problems. Capacitive and resistive sensors can detect water levels well below visual detection limits, preventing the extensive damage that water contamination can cause in hydraulic systems.

Hydraulic Fluid Contamination Prevention Strategies

Advanced Filtration System Design

Effective contamination control requires properly designed filtration systems that address both existing contamination and prevent new contamination ingress. Multi-stage filtration strategies provide the most effective contamination control by addressing different contamination types and sources throughout the system.

Return line filtration represents the most cost-effective contamination control investment for most hydraulic systems. Return filters capture wear particles and contamination before they recirculate through the system, providing continuous contamination removal during system operation.

Pressure line filtration protects sensitive components like servo valves from contamination that bypasses return filtration. High-pressure filters must withstand system pressure while providing fine filtration, making proper selection critical for reliable operation.

Kidney loop filtration systems provide supplemental contamination control by continuously filtering fluid from the reservoir through dedicated filtration circuits. These systems can achieve very low contamination levels and often include water removal capabilities for comprehensive fluid conditioning.

Breather filtration prevents atmospheric contamination from entering the system through reservoir breathing. Quality breather assemblies include both particle and moisture filtration to protect the reservoir from environmental contamination.

Proper Fluid Handling Procedures

Contamination-free fluid handling requires systematic procedures and proper equipment to prevent contamination introduction during fluid transfer and storage operations. Many systems receive more contamination during maintenance activities than they generate during normal operation.

Clean fluid transfer systems eliminate contamination sources during fluid handling operations. Dedicated transfer pumps, clean hoses, and proper connection procedures prevent contamination introduction that can immediately compromise freshly serviced systems.

Fluid storage practices significantly affect contamination levels in hydraulic systems. Proper drum handling, clean storage areas, and contamination-free dispensing systems maintain fluid quality from delivery through system installation.

New fluid verification through testing ensures that fresh fluid meets system requirements before installation. Many bulk fluid suppliers provide contamination levels that exceed system requirements, making filtration or alternative sourcing necessary for sensitive applications.

System Design for Contamination Control

Proper system design includes features that minimize contamination generation and facilitate contamination removal. Reservoir design significantly affects contamination control by providing settlement areas for contaminants and proper fluid conditioning before recirculation.

Reservoir baffling creates quiet zones where contaminants can settle while preventing direct return flow from mixing with suction flow. Proper baffle design ensures adequate residence time for contamination settlement and air separation while maintaining adequate flow capacity.

System flushing provisions enable thorough cleaning during commissioning and major maintenance activities. Temporary connections and bypass circuits allow turbulent flow flushing without disassembling components, ensuring thorough contamination removal while minimizing reassembly contamination.

Industry-Specific Contamination Challenges

Mobile Equipment Applications

- Mobile hydraulic systems face extreme contamination challenges due to harsh operating environments and limited maintenance access. Construction equipment, agricultural machinery, and mining vehicles operate in conditions that can overwhelm even well-designed contamination control systems.

- Environmental sealing becomes critical for mobile applications where direct contamination exposure is unavoidable. Heavy-duty seals, protective covers, and proper component orientation help minimize contamination ingress while maintaining accessibility for maintenance operations.

- Filtration capacity must accommodate extreme contamination loads without frequent maintenance. Bypass filtration systems and high-capacity filter elements extend service intervals while maintaining protection levels.

Manufacturing and Process Industries

- Precision manufacturing applications require extremely low contamination levels to maintain product quality and process reliability. Clean room requirements, sensitive process equipment, and quality control considerations make contamination control critical for operational success.

- Process contamination from manufacturing operations can introduce specialized contaminants that require specific filtration approaches. Metal cutting operations generate precisely sized metallic particles, while chemical processes may introduce corrosive contaminants requiring specialized filtration media.

- Quality control integration links hydraulic system contamination levels to product quality requirements. Statistical process control methods can identify contamination-related quality problems and optimize contamination control investments based on product quality requirements.

Cost-Benefit Analysis of Contamination Control

Investment Requirements and Returns

Comprehensive contamination control requires initial investment in filtration systems, monitoring equipment, and proper maintenance procedures. However, the return on investment typically exceeds 300-500% within the first year through reduced maintenance costs and improved reliability.

Filtration system upgrades represent the most cost-effective contamination control investment for most applications. Quality filtration systems typically cost less than a single major component replacement while providing protection throughout the system lifecycle.

Component life extension from effective contamination control often doubles or triples normal service intervals. Hydraulic pumps and motors that might require overhaul after 2,000 hours in contaminated systems often operate reliably for 8,000-10,000 hours with proper contamination control.

Energy efficiency improvements from contamination control reduce operating costs throughout the equipment lifecycle. Clean systems operate more efficiently with lower power consumption, providing ongoing savings that continue accumulating over years of operation.

Future Trends in Contamination Control

Advanced sensor technologies provide more detailed contamination analysis and enable predictive maintenance approaches that optimize contamination control investments. Wireless monitoring systems enable remote contamination monitoring and trending analysis that improves maintenance scheduling and resource allocation.

Next-generation filtration media and system designs provide improved contamination control while reducing operating costs and maintenance requirements. Self-cleaning filtration systems reduce maintenance requirements while maintaining consistent filtration performance.

Conclusion

Hydraulic fluid contamination represents one of the most serious threats to hydraulic system reliability and performance. Understanding contamination sources, effects, and prevention strategies enables maintenance professionals to protect their investments while maximizing operational efficiency and equipment life.

The key to successful contamination control lies in systematic approaches that address contamination sources, provide effective removal capabilities, and monitor system condition to enable proactive maintenance. Prevention costs far less than reactive maintenance and provides ongoing benefits through improved reliability and performance.

Implementing comprehensive contamination control requires initial investment in proper equipment and procedures, but the returns through reduced maintenance costs, extended component life, and improved reliability typically exceed the investment within the first year.

At DuraFilter, our three decades of hydraulic system experience provides expertise in contamination control solutions. From high-quality filter elements designed for demanding applications to complete hydraulic system solutions, we help customers implement contamination control strategies that protect their investments and maximize operational performance.

FAQs :

1. What is hydraulic fluid contamination?

Hydraulic fluid contamination occurs when unwanted substances such as dust, moisture, air, metal debris or chemically broken-down oil enter the hydraulic system, stopping the fluid from lubricating and transferring power effectively, causing higher friction, accelerated wear, sludge buildup and eventual component damage, even from particles under 5 microns.

2. What causes hydraulic fluid contamination?

Hydraulic fluid contamination occurs due to dirty reservoirs, worn seals, poor or clogged filtration, and improper maintenance practices. Dust, moisture, and metal particles can enter during operation or servicing, leading to fluid degradation and component wear.

3. Why is hydraulic fluid contamination dangerous?

Hydraulic fluid contamination is dangerous because dirt, water, and metal particles damage internal components, reduce lubrication, and block critical valves. This leads to overheating, power loss, pump failure, and costly system breakdowns if not addressed quickly.

4. What is hydraulic system contaminant removal?

It is the process of cleaning hydraulic fluid and components to remove dirt, water, and other impurities that can damage the system. Regular removal keeps the system efficient and prolongs equipment life.

5. How can I prevent hydraulic fluid contamination?

You can prevent hydraulic fluid contamination by using high-quality filtration, keeping reservoirs sealed, and replacing oil and filters at recommended intervals. Maintaining clean tools and work areas during servicing also helps stop dirt and moisture from entering the system.