Understanding Hydraulic Safety Valves

Hydraulic safety valves are an essential component in any pressurized hydraulic system. Their primary purpose is to ensure that the pressure within the system remains within safe operational limits. Excess pressure can cause damage to pumps, actuators, and hoses, leading to system failures or hazardous situations. By installing a safety valve, hydraulic systems can automatically release pressure when it exceeds the pre-set threshold, protecting equipment and personnel.

At DURAfilter, we provide a wide range of hydraulic safety valves designed for industrial, mobile, and energy applications. Each valve is engineered to deliver consistent performance, quick response time, and minimal leakage, ensuring that the system remains efficient and safe under variable load conditions.

The Importance of Safety Valve Hydraulic Systems

A safety valve hydraulic system acts as the final safeguard against overpressure events. It maintains the balance between system pressure and operational safety. When hydraulic pressure rises above the design limit, the valve opens to divert fluid back to the tank or low-pressure area, ensuring safe operation of the entire circuit.

Without a properly functioning safety valve, even a minor blockage or malfunction in the hydraulic line can cause extreme pressure surges. These surges not only compromise system components but can also result in costly downtime and potential safety hazards. By integrating a reliable safety valve hydraulic configuration, operators ensure uninterrupted performance and extended equipment lifespan.

Features of Hydraulic Safety Valve

Our safety valves are precision-engineered and easily adjustable to meet specific pressure relief requirements.

- Their robust design ensures durability under extreme pressure conditions.

- They are manufactured using high-quality materials, including stainless steel, for corrosion resistance.

- These safety valves are available in multiple sizes and pressure settings to suit different applications.

- They conform to international standards such as ASME, API, and EN.

- Our pressure safety valve requires low maintenance, ensuring long-term performance.

- They can be used in conjunction with other control components for enhanced system safety.

How Hydraulic Safety Valves Work?

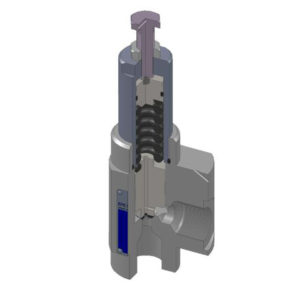

Hydraulic safety valves operate through a simple yet effective mechanism. When the system pressure reaches a predetermined limit, the valve’s internal spring force is overcome by the pressure acting on the valve seat. This causes the valve to open, allowing excess hydraulic fluid to flow to a return line or reservoir. Once the pressure drops back to the safe range, the spring reseats the valve to close the passage.

This automatic operation ensures continuous protection without the need for manual intervention. DURAfilter’s safety valves are designed for quick response, ensuring minimal lag between pressure buildup and valve activation. This responsiveness is critical in preventing damage to sensitive hydraulic components and maintaining overall system efficiency.

Types of Hydraulic Safety Valves Available

1. Spring-Loaded Hydraulic Safety Valves

These valves use a spring mechanism to control opening and closing. They are ideal for general-purpose applications where system pressure remains relatively stable. The spring tension determines the set pressure at which the valve opens.

2. Pilot-Operated Hydraulic Safety Valves

In pilot-operated models, a small pilot valve controls the main valve’s operation. These valves offer greater precision and are suitable for high-pressure systems requiring minimal pressure fluctuation. They are commonly used in large industrial machinery and energy systems.

3. Balanced-Bellows Hydraulic Safety Valves

Balanced-bellows designs compensate for backpressure and ensure stable performance even in fluctuating discharge conditions. They are widely used in chemical processing plants, refineries, and power generation units where backpressure effects are significant.

Design and Construction of DURAfilter Hydraulic Safety Valves

DURAfilter hydraulic safety valves are built using high-grade stainless steel, carbon steel, and specialized alloys to ensure corrosion resistance and mechanical strength. Each valve undergoes rigorous testing for pressure capacity, leakage, and response time.

Key design elements include:

- Precision machining for accurate pressure settings

- Hardened valve seats to minimize wear under repeated operation

- Compact body design for easy integration into hydraulic systems

- Adjustable set points for flexible use across different applications

These design attributes make DURAfilter’s safety valves ideal for both new installations and retrofit projects.

Applications of Hydraulic and Accumulator Safety Valves

- Steam boilers and pressure vessels

- Chemical processing units

- Oil and gas pipelines

- HVAC and compressed air systems

- Water treatment and power generation

- Mobile hydraulic equipment

- Construction machinery

- Renewable energy systems such as wind turbines and hydroelectric plants

Whether used in a hydraulic power pack or an accumulator circuit, these valves play an essential role in maintaining system integrity across multiple industries.

Advantages of DURAfilter Safety Valves

- High accuracy: Consistent pressure release ensures stable operation.

- Long service life: Corrosion-resistant materials and precision machining extend product lifespan.

- Compact design: Easy to install and maintain within confined hydraulic circuits.

- Custom pressure settings: Adjustable according to system requirements.

- Reliable sealing: Prevents internal leakage for improved efficiency.

- Low maintenance: Designed for long-term performance with minimal upkeep.

These advantages make DURAfilter’s safety valves a preferred choice for engineers and maintenance professionals seeking performance and reliability.

Selecting the Right Safety Valve Hydraulic System

Choosing the right safety valve for your hydraulic application requires understanding the system’s operating pressure, temperature, and flow characteristics. Key factors include:

- Set Pressure: The pressure at which the valve opens should be slightly above normal operating pressure to ensure optimal protection.

- Flow Rate: Select a valve that can discharge sufficient fluid volume during overpressure events.

- Medium Compatibility: Ensure that the valve material is compatible with hydraulic fluids used in the system.

- Temperature Range: The valve should maintain functionality across the full operating temperature spectrum.

- Installation Orientation: Consider the layout of the hydraulic circuit to minimize pressure drop and ensure easy maintenance.

DURAfilter’s technical team assists customers in selecting and configuring the ideal hydraulic safety valve solution based on these parameters.

Maintenance and Testing of Hydraulic Safety Valves

Regular maintenance is essential to keep hydraulic safety valves operating efficiently. Over time, system vibrations, fluid contamination, or corrosion may affect the valve’s performance. It is recommended to:

- Inspect the valve periodically for leakage or corrosion.

- Verify the set pressure using calibrated testing equipment.

- Clean internal parts to remove contaminants or sludge.

- Replace worn-out seals and springs as part of preventive maintenance.

DURAfilter provides maintenance kits and service support to ensure your accumulator safety valves and hydraulic safety valves remain in top working condition throughout their service life.

FAQs

Q. What is the purpose of a hydraulic safety valve?

Ans. A hydraulic safety valve prevents excessive pressure in hydraulic systems by automatically releasing fluid when the pressure exceeds a set limit.

Q. How often should safety valves be tested?

Ans. Safety valves should be inspected at least once a year and tested based on system usage, operating conditions, and industry standards.

Q. Can I use the same valve for hydraulic oil and water-glycol fluids?

Ans. Yes, but you must confirm material compatibility. Stainless steel or brass valves typically perform well with different hydraulic media.

Q. Do you offer custom pressure settings?

Ans. Yes, DURAfilter provides adjustable and custom-set pressure configurations to match your exact system requirements.