Modern farming has transformed into a highly mechanized and technology-driven industry. From tractors and harvesters to loaders and sprayers, almost every essential piece of farm machinery depends on Agricultural Hydraulic Systems. These systems provide the power, precision and control needed to perform demanding tasks in the field. As agriculture continues to evolve, the Importance of Hydraulics in Agricultural machinery has grown even stronger, supporting heavy workloads, improving speed and enabling better productivity. This blog explores the role, components, challenges and maintenance needs of hydraulic systems in modern agriculture, helping farmers understand how to keep their machinery running smoothly and efficiently. Hydraulic technology has become the backbone of modern farm operations. Whether it’s lifting heavy loads, powering attachments, steering equipment, or controlling motion, Hydraulics in Agriculture provides the force and responsiveness machines need in demanding environments. These systems help tractors, harvesters, balers and other implements work with consistent motion, stability and efficiency. The Importance of Hydraulics in Agricultural work becomes clear when you look at how many everyday tasks depend on it lifting hay bales, operating loaders, steering machinery, powering sprayers and enabling smooth harvesting processes. Without reliable hydraulic power, farming operations would slow down significantly and require more manual labor. Hydraulics makes agricultural work faster, safer and more productive, especially in large-scale or commercial farming. The Role of Hydraulics in Agricultural machinery is crucial because it enables essential functions that mechanical or electrical systems alone cannot achieve. Hydraulic systems provide high power output with compact components, making them ideal for bulky and heavy-duty farm machines. Here’s how Hydraulic systems in agricultural equipment contribute to efficient operations: Thanks to their strength and reliability, Hydraulic Systems in Modern Agriculture are now essential for every major farming operation, from land preparation to post-harvest work. A complete hydraulic setup consists of several critical parts that work together to move fluid, generate force and support machine operations. Understanding Agricultural Hydraulic Components helps in maintaining the system effectively and identifying issues early. Here are the major components found in Agricultural Hydraulic Systems: Each component plays a vital role in keeping Hydraulic systems in agricultural machinery running at peak performance. If even one part fails, the entire system can become inefficient or unsafe. One of the biggest challenges faced by Agricultural Hydraulic Systems is contamination. Farming environments expose machinery to dust, mud, moisture, crop debris and harsh weather. These contaminants can easily enter the hydraulic fluid through damaged seals, worn hoses, or during improper maintenance. Contamination is one of the most common causes of failure in Hydraulic Systems in Modern Agriculture. Even tiny particles can severely damage pumps and cylinders, leading to expensive repairs or machine downtime. Moisture from rain, humidity, or washdowns can also mix with hydraulic fluid, causing oxidation, corrosion and thickening of the oil. This reduces lubrication and increases friction, making the system work harder. Because contamination is unavoidable in the agricultural environment, the best defense is proper filtration and regular maintenance. Learn More About: Hydraulic fluid contamination Agricultural Hydraulic Filters play a critical role in keeping the system clean, safe and efficient. They trap contaminants before they can circulate through pumps, valves, and cylinders, reducing breakdown risk. Filters keep fluid clean by removing dirt, metal particles, moisture, and sludge. With clean hydraulic fluid, machinery can operate smoothly for longer hours, especially during high-demand seasons like planting and harvesting. Replacing Agricultural Hydraulic Filters at recommended intervals is one of the simplest yet most important maintenance tasks for prolonging machine life. Even with strong designs and durable components, common hydraulic system issues in agricultural machinery can still occur due to harsh field conditions. Understanding these problems early helps prevent major failures and ensures consistent performance. To keep hydraulic systems in agricultural equipment functioning properly, follow these essential maintenance practices: With proper care, agricultural hydraulic systems can perform reliably for several years, even in challenging farm environments. Hydraulics plays an essential role in making modern agriculture efficient, productive, and safe. From lifting heavy loads to powering implements and ensuring smooth steering, hydraulic systems in modern agriculture are the driving force behind day-to-day operations. Understanding the role of hydraulics in agricultural machinery, recognizing common issues and performing regular maintenance especially filter care helps protect equipment and improve performance. By focusing on clean fluid, strong components and timely maintenance, farmers can ensure their machines operate smoothly throughout the farming season, reducing breakdowns and maximizing productivity. Reliable hydraulics in agriculture is not just a technological advantage it’s a necessity for meeting today’s high agricultural demands.

Importance of Hydraulics in Agricultural OperationsRole of Hydraulics in Agricultural Machinery

Agricultural Hydraulic Systems & Their Key Components

Contamination Issues in Agricultural Hydraulic Systems

Impact of Contamination

Water Contamination

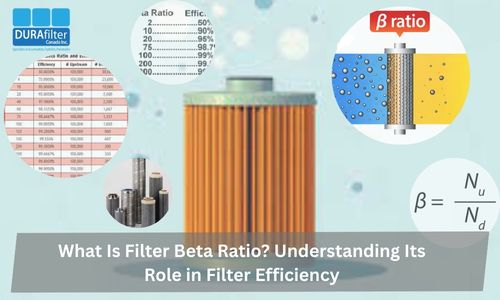

Importance of Agricultural Hydraulic Filters in System Protection and Maintenance

Why Hydraulic Filters Are Essential

Types of Hydraulic Filters

Common Hydraulic System Issues in Agricultural Machinery & How to Maintain Them

Common Issues:

Maintenance Tips to Avoid Hydraulic Issues

Conclusion

Why Hydraulic Systems Matter in Modern Agriculture: Roles, Challenges and Maintenance

Recent Blogs