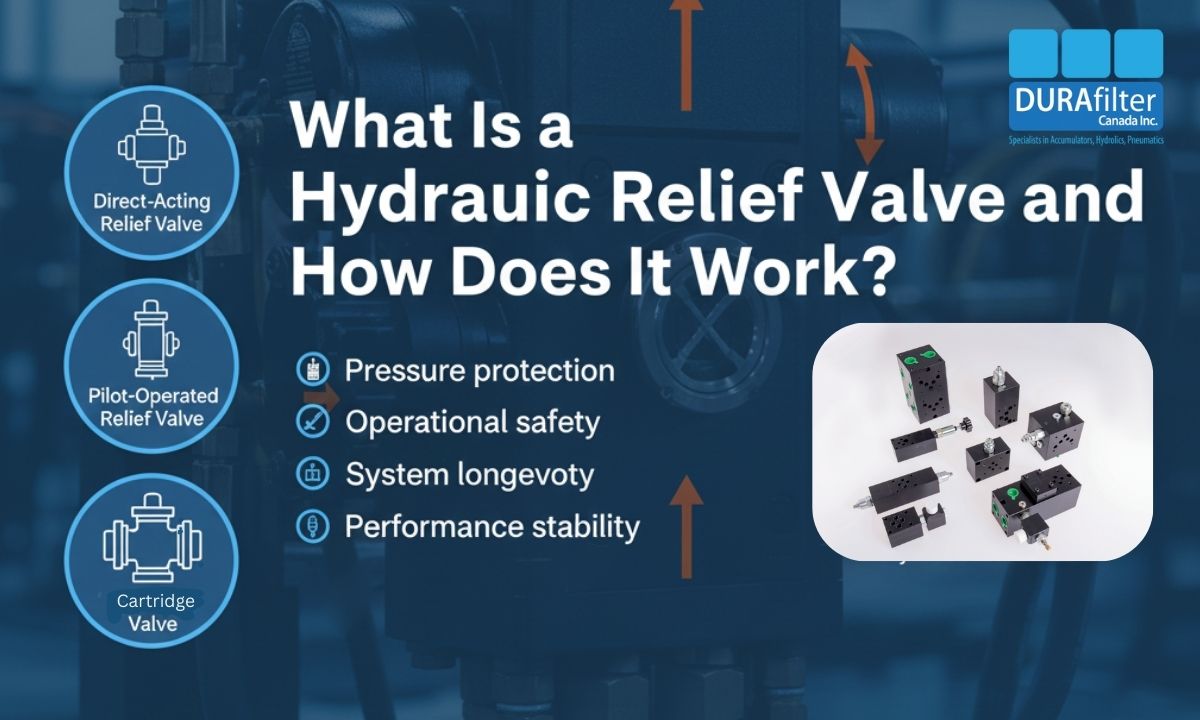

Hydraulic systems play a vital role in modern industrial operations, providing dependable power for manufacturing, construction, agriculture and heavy-duty equipment across the United States. Although these systems are built for performance and durability, uncontrolled pressure can pose serious risks. Excessive hydraulic pressure can damage components, lead to unplanned downtime and create safety concerns for operators. This makes it essential for engineers, operators and maintenance professionals to understand the function of Hydraulic Valves in pressure control. A hydraulic relief valve is a critical safety component within Hydraulic Valves, designed to protect hydraulic systems from overpressure by automatically releasing excess fluid when pressure exceeds safe limits. Whether used in compact mobile equipment or large industrial power units, relief valves help maintain stable operating conditions, improve system reliability and extend overall equipment life. What is a hydraulic relief valve? A hydraulic relief valve is a pressure-control device designed to limit the maximum pressure within a hydraulic circuit. When system pressure exceeds a preset value, the valve opens and diverts excess fluid back to the reservoir or another safe path, preventing pressure buildup that could damage pumps, hoses, seals, or actuators. In simple terms, a Hydraulic Relief Valve acts as a safety guard for the entire hydraulic system. Without it, pressure spikes caused by load changes, blocked lines, or thermal expansion could lead to catastrophic failures. This is why a relief valve in hydraulic system design is considered a mandatory safety component rather than an optional accessory. From real-world industrial experience, systems operating without a reliable hydraulic pressure relief valve often suffer from premature wear, frequent downtime and higher maintenance costs. By maintaining pressure within safe operating limits, the valve ensures predictable system behavior and protects high-value equipment. To know more about Hydraulic Valves click here. The working principle of a hydraulic pressure relief valve is based on force balance. Inside the valve, a spring or pilot mechanism holds the valve closed under normal operating pressure. When hydraulic pressure reaches the preset limit, the force exerted by the fluid overcomes the spring force, causing the valve to open. Once open, the pressure relief valve hydraulic mechanism allows excess fluid to flow away from the pressurized line. This immediate pressure reduction prevents further pressure rise and stabilizes the system. When pressure drops back to a safe level, the valve closes automatically, restoring normal operation. This automatic response makes the Hydraulic Relief Valve a self-regulating component that requires minimal operator intervention. In complex circuits using Industrial Hydraulic Valves, relief valves are often integrated into manifolds or Hydraulic Relief Valve Blocks to protect multiple circuits simultaneously. Key stages of operation include: This simple yet robust mechanism is the reason hydraulic relief valves are trusted across industries for continuous, high-load operations. The role of a relief valve in hydraulic system architecture goes far beyond basic pressure control. Its primary function is safety, but its impact on system efficiency and reliability is equally significant. By limiting maximum pressure, the valve protects pumps from overload, prevents hose rupturef and reduces stress on seals and fittings. In real industrial environments, pressure fluctuations are unavoidable due to varying loads and operating conditions. A well-calibrated Hydraulic Relief Valve absorbs these fluctuations, maintaining stable pressure and ensuring smooth actuator movement. This stability is crucial in precision machinery where even minor pressure variations can affect product quality. Additionally, relief valves support compliance with safety standards and regulations. Many industrial safety guidelines require the use of Hydraulic Safety Valves to minimize the risk of accidents caused by hydraulic failures. A relief valve in hydraulic system design plays a vital role in ensuring safe, efficient and reliable operation. By automatically controlling excess pressure, a Hydraulic Relief Valve protects critical components and supports long-term system performance. Whether you are designing a new circuit or upgrading existing equipment, integrating the right valve is essential for optimal results. One of the key advantages of a hydraulic pressure relief valve is pressure protection. Sudden pressure spikes can damage pumps, cylinders and hoses, but a properly set valve releases excess fluid before harm occurs. This makes the pressure relief valve hydraulic an essential safety component in modern hydraulic systems. Key benefits include: By using a high-quality industrial hydraulic relief valve, systems operate more efficiently and experience less downtime. Modern industries use several types of industrial hydraulic relief valve designs, each suited for specific operating conditions. The two most common types are direct-acting and pilot-operated relief valves. Direct-acting valves are simple in design and respond quickly to pressure changes. The hydraulic pressure acts directly on the valve poppet against a spring. These valves are ideal for low-flow or secondary circuits where fast response is required. Pilot-operated valves use a two-stage design, offering greater stability and accuracy at higher flow rates. They are commonly used as pressure relief valve hydraulic solutions in heavy-duty industrial systems where precise pressure control is essential. Both types are widely used within Industrial Hydraulic Valves portfolios and are often combined with Hydraulic Safety Valves for enhanced protection. Other Types & Variations Explore detailed specifications of Industrial Hydraulic Valves click here. A pressure relief valve hydraulic is used wherever controlled pressure is essential for safe and reliable operation. Industrial Applications Manufacturing plants rely heavily on industrial hydraulic relief valve solutions in: These systems often incorporate Hydraulic Relief Valve Blocks to manage pressure across multiple circuits. Mobile and Heavy-Duty Equipment Construction, mining and agricultural machinery use a relief valve in hydraulic system to protect components under variable loads. Excavators, loaders and cranes depend on hydraulic pressure relief valve performance to ensure smooth and safe operation. Power Generation and Process Industries In power plants and chemical processing units, Hydraulic Safety Valves prevent damage caused by thermal expansion and sudden pressure surges. Here, reliable Industrial Hydraulic Valves are essential for compliance with safety and operational standards. A Hydraulic Relief Valve is not just a component; it is the foundation of safe and reliable hydraulic system operation. By understanding what is a hydraulic relief valve, how it works and how it fits into a complete system, engineers and operators can make informed decisions that improve safety, efficiency and equipment life. Whether used as a standalone relief valve in hydraulic system design or integrated into advanced Hydraulic Relief Valve Blocks, this essential device ensures pressure never exceeds safe limits. Investing in the right pressure relief valve hydraulic solution today can prevent costly failures tomorrow and keep your hydraulic systems operating at peak performance. Need help selecting the right hydraulic pressure relief valve for your system? Contact Durafilter today to speak with our hydraulic solutions experts. 1. How does a hydraulic relief valve work? A hydraulic relief valve works by automatically opening when system pressure exceeds a preset limit. The excess hydraulic fluid is diverted to the reservoir, reducing pressure and protecting system components. Once pressure returns to a safe level, the valve closes and normal operation resumes. 2. How to adjust relief valve hydraulic? To adjust a hydraulic relief valve, loosen the lock nut and turn the adjustment screw while monitoring system pressure with a gauge. Turning the screw clockwise increases pressure, while turning it counterclockwise decreases pressure. Always adjust gradually and test under operating conditions to ensure safe pressure limits. 3. What happens when a pressure relief valve goes bad? If a pressure relief valve (PRV) fails, it can cause dangerous pressure buildup or uncontrolled pressure release, leading to system instability. A stuck-closed valve may result in ruptures, explosions or severe equipment damage, while a stuck-open or leaking valve causes pressure loss and operational failure. Both conditions increase safety risks, downtime and component wear. 4. What happens if a relief valve fails? If a relief valve fails, hydraulic pressure can rise beyond safe limits, leading to pump damage, hose rupture or seal failure. This can cause sudden system shutdowns, oil leakage and serious safety risks. Prolonged operation without pressure relief may result in costly equipment damage and downtime. 5. What are the symptoms of a faulty valve? Symptoms of a faulty valve include unstable or excessive system pressure, unusual noises such as whining or chattering, and overheating of hydraulic oil. You may also notice slow, jerky actuator movement along with frequent leaks or premature component wear. What Is a Hydraulic Relief Valve?

How a Hydraulic Pressure Relief Valve Works

Role of Relief Valve in a Hydraulic System

Benefits of a Relief Valve in Hydraulic System Design

Benefit

Impact on System

Pressure protection

Prevents component damage and sudden failure

Operational safety

Reduces risk of accidents and oil leakage

System longevity

Extends the life of pumps, hoses and seals

Performance stability

Maintains consistent and controlled pressure

Types of Hydraulic Relief Valves Used in Industry

Common Uses of Hydraulic Pressure Relief Valves

Conclusion

FAQs :

What Is a Hydraulic Relief Valve and How Does It Work?

Recent Blogs