When your hydraulic equipment starts losing power, every minute of downtime translates directly to lost productivity and mounting costs. Whether it’s a construction excavator that can’t lift its rated capacity, a manufacturing press that cycles slower than specification, or an injection molding machine that fails to maintain proper clamping force, hydraulic power loss demands immediate attention and systematic diagnosis.

Hydraulic failure doesn’t happen overnight. It’s typically the result of gradual degradation that manifests as reduced performance before complete system breakdown. Understanding the root causes and implementing proper hydraulic troubleshooting procedures can mean the difference between a quick fix and a devastating failure requiring major repairs or equipment replacement.

This detail guide provides maintenance professionals, equipment operators, and facility managers with proven hydraulic system troubleshooting methodologies to diagnose power loss issues quickly and accurately. By following systematic diagnostic procedures, you can identify problems early, minimize downtime, and extend equipment life while avoiding the costly mistakes that often accompany rushed troubleshooting efforts.

Understanding Power Loss in Hydraulic Systems

Hydraulic power loss indicates in several ways that experienced technicians learn to recognize. The most obvious symptom is reduced force output when cylinders can’t lift their rated loads or motors can’t provide specified torque. However, power loss also appears as slower cycle times, erratic operation, excessive heating, and inability to maintain system pressure under load.

True hydraulic power is the product of pressure and flow rate. When either parameter drops below design specifications, total power output decreases proportionally. A system rated for 3,000 PSI at 20 GPM should deliver approximately 25 horsepower. If pressure drops to 2,500 PSI due to internal leakage, power output falls to roughly 21 horsepower, a 16% reduction that significantly impacts equipment performance.

The challenge in hydraulic system troubleshooting lies in distinguishing between symptoms and root causes. Reduced pressure might result from pump wear, relief valve problems, internal leakage, or even something as simple as low fluid levels. Systematic diagnosis prevents the costly mistake of replacing expensive components when simpler solutions exist.

Understanding normal system behavior provides the baseline for effective troubleshooting. Document normal operating pressures, temperatures, cycle times, and fluid levels when equipment is functioning properly. This baseline data becomes invaluable when hydraulic failure symptoms appear, enabling quick identification of parameters that have changed from normal operation.

Primary Causes of Hydraulic Power Loss

Pump-Related Issues

- Hydraulic pumps represent the heart of any hydraulic system, and pump degradation is often the primary reason in power loss scenarios. Internal wear creates clearances that allow pressurized fluid to leak internally rather than flowing to system actuators. This internal leakage reduces both pressure and available flow, directly impacting system power output.

- Pump cavitation represents another common cause of hydraulic failure. When pumps cannot draw adequate fluid from the reservoir, cavitation bubbles form and collapse violently, causing noise, vibration, and rapid component wear. Cavitation symptoms include excessive noise, erratic operation, and accelerated pump degradation that leads to further power loss.

- Variable displacement pumps add complexity to hydraulic troubleshooting procedures. Control system problems can prevent these pumps from achieving full displacement, limiting flow output even when the pump mechanism remains mechanically sound. Pilot pressure issues, contaminated control valves, or electronic control malfunctions can all limit pump displacement and reduce system power.

- Drive coupling problems between prime movers and hydraulic pumps can also cause power loss symptoms. Worn couplings, misalignment, or slipping drive connections prevent full power transmission from the motor to the pump, resulting in reduced hydraulic power output that mimics internal pump problems.

Fluid-Related Problems

- Hydraulic fluid serves multiple critical functions beyond power transmission, and fluid problems often contribute to power loss issues. Contaminated fluid accelerates component wear, leading to increased internal leakage and reduced efficiency. Water contamination particularly damages hydraulic systems by promoting corrosion, reducing lubrication effectiveness, and causing unpredictable system behavior.

- Incorrect fluid viscosity significantly impacts system performance. Fluid that’s too thick increases flow resistance and power consumption while potentially causing cavitation at the pump inlet. Conversely, fluid that’s too thin provides inadequate lubrication and allows excessive internal leakage, both of which reduce system efficiency and power output.

- Temperature-related fluid problem is perceived as power loss through multiple mechanisms. Overheated fluid loses viscosity, increasing internal leakage throughout the system. High temperatures also accelerate fluid breakdown, creating varnish deposits that restrict valve operation and reduce flow capacity. Cold fluid, conversely, increases viscosity to levels that may prevent proper system startup and operation.

- Low fluid levels create multiple problems that contribute to hydraulic failure. Insufficient fluid in the reservoir can cause pump cavitation, introduce air into the system, and reduce heat dissipation capacity. These conditions combine to accelerate component wear and reduce system efficiency, creating a cascade of problems that worsen over time.

Filtration and Contamination Issues

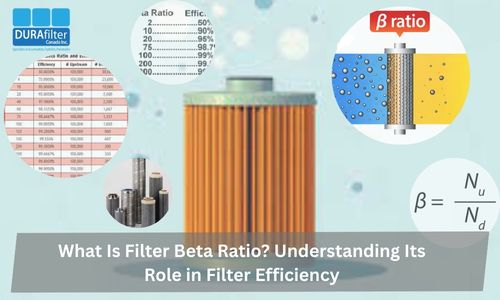

Effective filtration is necessary for hydraulic system reliability, and filtration problems often contribute to power loss through component damage and flow restrictions. Clogged filter elements create pressure drops that reduce available system pressure and may force fluid through filter bypass circuits, allowing contamination to accelerate component wear.

Contamination damage in hydraulic systems typically develops gradually, making it difficult to detect until significant power loss occurs. Particulate contamination causes abrasive wear in pumps, valves, and actuators, increasing internal leakage and reducing efficiency. The ISO 4406 cleanliness standard provides guidelines for acceptable contamination levels, but many systems operate far above these recommendations.

Bypassed or malfunctioning filtration systems allow contamination to circulate freely, accelerating the wear process and reducing system life. Regular filter maintenance and monitoring differential pressure across filter elements provides early warning of filtration problems before they contribute to hydraulic failure.

Valve and Control Issues

Control valves throughout hydraulic systems can contribute to power loss through internal leakage, incorrect adjustment, or complete malfunction. Relief valves set too low limit maximum system pressure, directly reducing power output. Internal leakage in directional control valves allows pressurized fluid to return to tank rather than powering actuators.

Proportional and servo valves require clean fluid and precise adjustment to function properly. Contamination can cause these precision components to stick or respond incorrectly, limiting flow to system actuators and reducing power output. The sensitivity of these valves to contamination makes them early indicators of filtration problems.

Flow control valves can contribute to power loss if they become restricted or fail in partially closed positions. Temperature-related expansion and contraction can affect valve settings, while contamination deposits can partially block flow passages, creating symptoms that mimic more serious hydraulic problems.

Systematic Hydraulic System Troubleshooting Approach

Effective hydraulic troubleshooting requires a systematic approach that prioritizes safety while efficiently identifying root causes. Rushing to conclusions or skipping diagnostic steps often leads to unnecessary component replacement and extended downtime. Professional technicians follow established procedures that minimize risks while maximizing diagnostic accuracy.

Safety and Initial Assessment

- Before beginning any hydraulic system troubleshooting, ensure proper lockout/tagout procedures are followed and all stored energy is safely released. Hydraulic systems can store significant energy in accumulators and trapped fluid, creating serious injury risks if not properly depressurized.

- Visual inspection provides valuable initial information about system condition. Look for obvious leaks, damaged components, loose connections, and signs of overheating. Check fluid levels and condition. Dark, thick, or contaminated fluid often indicates underlying problems that contribute to power loss.

- Document baseline measurements of key system parameters including pressure, temperature, and fluid levels. These measurements provide reference points for comparison with normal operating conditions and help track improvement after repairs are completed.

Pressure Testing and Analysis

- Systematic pressure testing forms the foundation of hydraulic system troubleshooting. Install pressure gauges at key points throughout the system including pump outlet, main system pressure, and individual branch circuits. This approach isolates problems to specific system sections and prevents unnecessary component replacement.

- Relief valve testing determines whether pressure limitations contribute to power loss. Temporarily install a higher-capacity relief valve or adjust the existing valve to determine if low pressure settings limit system performance. Be cautious not to exceed component pressure ratings during this testing.

- Load testing reveals system performance under actual operating conditions. Many hydraulic problems only reflect under load, making no-load testing inadequate for complete diagnosis. Document pressure levels with and without load to identify internal leakage or inadequate system capacity.

- Branch circuit testing isolates problems to specific system functions. By testing individual cylinders, motors, or valve circuits separately, technicians can determine whether power loss affects the entire system or only specific functions, significantly narrowing the diagnostic focus.

Flow Rate Analysis and Component Testing

- Flow measurement provides essential diagnostic information about system performance and component condition. Portable flow meters enable accurate measurement at various system points, revealing whether power loss results from reduced flow capacity or pressure limitations.

- Pump performance testing compares actual output with manufacturer specifications. Test pump flow and pressure output under various load conditions to determine whether pump degradation contributes to power loss. Document results for comparison with normal performance data.

- Actuator testing isolates cylinder and motor performance from system problems. Test individual actuators separately to determine whether power loss affects all system functions or only specific components. This approach prevents unnecessary system-wide repairs when only individual components require attention.

Component-Specific Diagnostic Procedures

Pump Diagnostics

- Pump condition assessment requires multiple diagnostic approaches to accurately determine internal wear and performance degradation. Pressure and flow testing provides quantitative data, while noise and vibration analysis reveals mechanical condition information not apparent from performance testing alone.

- Internal leakage testing determines pump volumetric efficiency by comparing actual flow output with theoretical output at various pressures. Significant internal leakage indicates worn internal clearances requiring pump overhaul or replacement. Document test results to track pump degradation over time.

- Case pressure testing on variable displacement pumps reveals control system problems that limit displacement and reduce flow output. High case pressure indicates internal leakage, while low case pressure may indicate control system malfunctions preventing full displacement achievement.

- Temperature monitoring during pump operation identifies overheating problems that accelerate wear and reduce efficiency. Abnormally high pump temperatures often indicate cavitation, excessive loading, or inadequate heat dissipation requiring immediate attention.

Actuator Performance Evaluation

- Cylinder and motor testing isolates actuator problems from system-wide issues, preventing unnecessary troubleshooting of components that function properly. Test individual actuators by isolating them from the system and supplying known flow and pressure inputs.

- Internal leakage measurement in cylinders determines seal condition and internal wear. Excessive internal leakage reduces actuator efficiency and speed while contributing to system heating and reduced overall performance. Document leakage rates for trend analysis and maintenance planning.

- Cushioning system evaluation identifies problems that cause harsh operation and accelerated wear. Malfunctioning cushioning systems create shock loads that damage seals, connections, and structural components while reducing operational smoothness and precision.

- Load holding capability testing determines whether actuators can maintain position under load. Poor load holding indicates seal problems or valve issues that require attention to prevent safety hazards and operational problems.

Advanced Troubleshooting Techniques

Modern hydraulic system troubleshooting benefits from advanced diagnostic technologies that provide detailed component condition information. Thermal imaging identifies overheating components before failure occurs, while vibration analysis detects bearing problems and internal wear not apparent through conventional testing.

Oil analysis trending provides early warning of component wear and fluid degradation. Regular sampling and testing reveals contamination trends, additive depletion, and wear particle generation that indicates developing problems before they cause hydraulic failure.

Electronic system diagnostics become increasingly important as hydraulic systems include more sophisticated control systems. Many modern systems include diagnostic capabilities that identify specific problem areas and guide troubleshooting efforts toward likely failure modes.

Preventing Common Troubleshooting Mistakes

Experience shows that certain troubleshooting mistakes occur repeatedly, often leading to unnecessary expense and extended downtime. Avoiding these common errors improves diagnostic accuracy while reducing troubleshooting time and cost.

- Never assume that obvious symptoms indicate the actual problem. Low system pressure might result from relief valve adjustment, pump wear, or even something as simple as a loose connection. Systematic testing prevents expensive component replacement when simple adjustments suffice.

- Don’t overlook fluid quality as a root cause of hydraulic failure. Contaminated, degraded, or incorrect fluid can cause symptoms that mimic expensive component problems. Always test fluid condition early in the diagnostic process to avoid misdirected troubleshooting efforts.

- Resist the temptation to replace multiple components simultaneously. This approach makes it impossible to determine which component actually failed and may mask underlying problems that will cause repeated failures. Replace components individually and test system performance after each replacement.

- Document all testing results and repair actions. This documentation provides valuable information for future troubleshooting efforts and helps identify recurring problems that indicate deeper system issues requiring comprehensive solutions.

Cost Impact and Professional Support

Delayed hydraulic troubleshooting costs far more than immediate attention to performance problems. Each day of reduced productivity compounds losses while system problems typically worsen over time, requiring more expensive repairs and longer downtime periods.

Complex hydraulic failure scenarios often require specialized diagnostic equipment and expertise beyond typical maintenance capabilities. Professional hydraulic specialists can quickly identify problems that might take internal maintenance teams significantly longer to diagnose, minimizing total downtime and repair costs.

When hydraulic system troubleshooting reveals major component damage or complex problems requiring specialized repair capabilities, partnering with experienced hydraulic repair services ensures quality work and reliable results. Professional repair services have the equipment, expertise, and component availability to complete repairs efficiently while maintaining quality standards.

Preventive Strategies

The best hydraulic troubleshooting is prevention through proactive maintenance and monitoring.

- Regular fluid analysis, filter replacement, and component inspection identify developing problems before they cause power loss and equipment failure.

- Implementing condition monitoring programs using pressure, temperature, and vibration sensors provides early warning of developing problems. Modern monitoring systems can alert maintenance personnel to problems before they impact production, enabling planned maintenance during scheduled downtime.

- Training maintenance personnel in proper hydraulic system troubleshooting techniques improves diagnostic accuracy while reducing the time required to identify and correct problems. Understanding hydraulic principles and systematic diagnostic procedures prevents costly mistakes while building internal expertise.

Conclusion

Hydraulic system troubleshooting requires systematic approaches that prioritize safety while efficiently identifying root causes of power loss. Understanding the relationship between pressure, flow, and power enables accurate diagnosis of performance problems before they become major failures.

The key to successful hydraulic troubleshooting lies in systematic testing, careful documentation, and logical problem-solving approaches that prevent costly mistakes. By following proven diagnostic procedures and avoiding common troubleshooting errors, maintenance professionals can minimize downtime while maximizing system reliability and performance.

At DuraFilter, our three decades of hydraulic system experience provides comprehensive support for complex troubleshooting challenges. From component diagnosis to complete hydraulic system solutions, our expertise helps customers identify problems quickly and implement effective solutions that restore equipment performance while preventing future failures.

Don’t let hydraulic power loss compromise your operational efficiency and profitability. Contact DuraFilter today for expert troubleshooting support and comprehensive hydraulic solutions that keep your equipment running at peak performance. Our technical expertise and quality components ensure reliable results when hydraulic system troubleshooting reveals problems requiring professional attention and specialized solutions.

FAQs :

1. What is hydraulic system troubleshooting?

Hydraulic system troubleshooting is the systematic process of diagnosing and fixing problems in a hydraulic system by inspecting its components and fluids. It involves checking for issues like leaks, low fluid levels and clogged filters and using tools and procedures such as pressure testing and listening for unusual sounds to identify and correct malfunctions.

2. How do you diagnose hydraulic system issues?

You can diagnose hydraulic system issues by checking for abnormal noises, slow operation, leaks, pressure drops and overheating, then inspecting components like pumps, valves, hoses and filters for faults. Basic tests include pressure checks, flow tests, and visual inspections to pinpoint the exact cause.

3. How do I check for hydraulic pressure problems?

To check for hydraulic pressure problems, start by inspecting fluid levels and for leaks, then use a pressure gauge to monitor system pressure under load. Other checks include listening for unusual noises, feeling for overheating and inspecting the filters, pump and relief valve for wear, blockages or incorrect settings.

4. What are advanced troubleshooting techniques in hydraulic systems?

Advanced techniques include pressure testing, flow analysis, thermal imaging and using diagnostic tools to detect internal leakage and component wear more accurately.

5. How can I prevent hydraulic failures?

Regularly check fluid levels, filters, hoses, and seals to catch wear early. Follow a preventive maintenance schedule to keep pressure, flow and components in proper condition.