Industrial operations depend heavily on the reliable performance of hydraulic systems. Whether you’re managing manufacturing equipment, construction machinery, or material handling systems, proper hydraulic system maintenance is the difference between smooth operations and unexpected, costly breakdowns. With over 30 years of experience in hydraulic solutions, we’ve seen firsthand how proactive maintenance strategies can save companies thousands of dollars while preventing dangerous equipment failures.

The stakes are high when hydraulic systems fail. Industry studies show that unplanned downtime can lead to significant losses for industrial facilities, impacting both productivity and operations. Beyond the immediate financial impact, hydraulic system failures can compromise worker safety, damage other equipment, and disrupt entire production schedules. Learn proven hydraulic system maintenance strategies that protect your investment and keep your operations running smoothly.

Understanding Your Hydraulic System Components

Before diving into maintenance procedures, it’s crucial to understand the key components that make your hydraulic system function. Each component plays a specific role, and knowing how they work together helps you identify potential problems before they escalate.

Hydraulic Pumps serve as the heart of your system, converting mechanical energy into hydraulic energy by moving fluid through the system. Signs of pump wear include unusual noise, reduced pressure output, and increased operating temperature. Regular monitoring of pump performance indicators can prevent catastrophic failure and extend equipment life.

Control Valves regulate flow direction, pressure, and flow rate throughout the system. These precision components are susceptible to contamination damage, which can cause erratic system behaviour, internal leakage, and complete valve failure. Proper filtration and regular valve inspection are essential for maintaining system control.

Actuators (cylinders and motors) convert hydraulic energy back into mechanical work. Seal wear, internal leakage, and contamination can significantly reduce actuator efficiency and force output. Regular inspection of rod seals, wipers, and cushioning systems prevents minor issues from becoming major repairs.

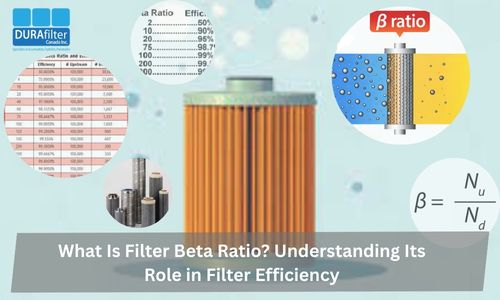

Hydraulic Filters protect your entire system by removing contaminants from the fluid. A quality filtration system is your first line of defence against contamination, the primary cause of hydraulic system failure. Understanding filter ratings, bypass indicators, and replacement intervals is fundamental to effective hydraulic system preventive maintenance.

Accumulators store pressurized fluid for peak demand periods and help smooth system operation. Pre-charge pressure monitoring and bladder/diaphragm inspection are critical maintenance tasks that prevent accumulator failure and maintain system performance.

Why Hydraulic System Preventive Maintenance is Non-Negotiable

The case for preventive maintenance becomes clear when you examine the numbers. Reactive maintenance is fixing problems after they occur, typically costs 3-5 times more than preventive maintenance. More importantly, reactive maintenance often leads to secondary damage that could have been completely avoided with proper servicing hydraulics on a scheduled basis.

- Reduced Downtime: Scheduled hydraulic system maintenance allows you to plan maintenance windows during non-production hours, eliminating surprise breakdowns during critical operations. Companies implementing comprehensive preventive maintenance programs report 30-50% reduction in unplanned downtime.

- Extended Equipment Life: Proper hydraulic system preventive maintenance can double or triple component life expectancy. Clean fluid, properly adjusted pressures, and timely component replacement prevent the accelerated wear that occurs when systems operate outside design parameters.

- Improved Energy Efficiency: Well-maintained hydraulic systems operate more efficiently, reducing energy consumption by 10-15%. Clean fluid, properly functioning pumps, and leak-free systems require less power to maintain operating pressure and flow rates.

- Enhanced Safety: Hydraulic system failures can create serious safety hazards, including high-pressure fluid injection injuries, slip hazards from leaking fluid, and equipment malfunction. Regular servicing hydraulics according to manufacturer specifications significantly reduces these safety risks.

- Cost Predictability: Preventive maintenance allows you to budget for maintenance expenses and avoid the unpredictable costs associated with emergency repairs, expedited parts shipping, and overtime labour charges.

Essential Hydraulic System Maintenance Tips

Fluid Management: The Foundation of System Health

- Regular Fluid Analysis: Implement a systematic fluid analysis program that tests for contamination levels, additive depletion, and fluid degradation. Monthly sampling for critical systems and quarterly sampling for less critical applications provides early warning of system problems. Key parameters to monitor include particle count, moisture content, acid number, and viscosity.

- Maintain Proper Fluid Levels: Check reservoir fluid levels daily during operation. Low fluid levels can cause pump cavitation, aeration, and overheating. Establish minimum and maximum fluid level indicators and train operators to recognize and report level changes that might indicate internal leakage.

- Temperature Monitoring: Hydraulic fluid temperature should typically remain below 140°F (60°C) for optimal performance and fluid life. Temperatures above 160°F (71°C) accelerate fluid breakdown and seal degradation. Install temperature monitoring systems and ensure adequate cooling capacity for your application.

Filtration: Your Primary Defense Against Contamination

- Filter Element Replacement: Establish filter replacement schedules based on differential pressure readings rather than arbitrary time intervals. Most hydraulic filters should be changed when differential pressure reaches 25 psi, though manufacturer specifications may vary. Keep detailed records of filter change intervals to identify trends that might indicate system problems.

- Multi-Stage Filtration Strategy: Implement return line filtration as a minimum, with suction strainers and pressure filtration for critical systems. Return line filters capture wear particles and contamination before they recirculate through the system. Pressure line filtration protects sensitive servo valves and proportional components.

- Bypass Indicator Monitoring: Modern hydraulic filters include bypass indicators that show when elements are loading with contaminants. Train maintenance personnel to check these indicators during routine inspections and replace elements before bypass occurs.

System Monitoring and Inspection Protocols

- Pressure and Flow Monitoring: Install gauges at key system points to monitor operating pressures and flow rates. Establish baseline readings for normal operation and investigate any significant deviations. Pressure spikes might indicate valve problems, while pressure drops could signal internal leakage or pump wear.

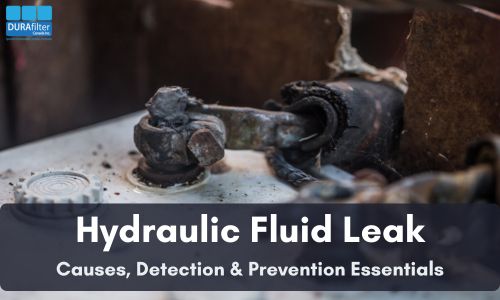

- Leak Detection and Repair: Implement a zero-tolerance policy for hydraulic leaks. External leaks waste fluid, create safety hazards, and often indicate more serious internal problems. Use UV dye and inspection lights to detect minor leaks that might not be visible during casual inspection.

- Hose and Fitting Inspection: Hydraulic hoses should be inspected monthly for signs of wear, cracking, or bulging. Pay special attention to hose routing near sharp edges, hot surfaces, and moving components. Replace hoses based on age even if they appear serviceable. Most hydraulic hoses should be replaced every 5-7 years regardless of appearance.

- Seal and Component Inspection: Look for signs of seal leakage, scoring on hydraulic rods, and unusual wear patterns on components. Early detection of seal problems allows for planned replacement before catastrophic failure occurs.

Servicing Hydraulics: Best Practices for Long-Term Success

Developing a Maintenance Schedule

- Risk-Based Maintenance Planning: Prioritize maintenance activities based on equipment criticality, failure consequences, and historical performance data. Critical systems might require weekly inspections, while less important systems could be serviced monthly or quarterly.

- Manufacturer Guidelines Compliance: Always follow OEM maintenance recommendations as your starting point, then adjust based on your operating conditions. Severe-duty applications require more frequent servicing hydraulics than standard industrial applications.

- Seasonal Considerations: Adjust maintenance schedules based on operating conditions. Cold weather operations might require more frequent fluid changes and seal inspections, while high-temperature environments demand enhanced cooling system maintenance.

Documentation and Record Keeping

- Maintenance History Tracking: Maintain detailed records of all hydraulic system maintenance activities, including fluid changes, filter replacements, component repairs, and system modifications. This historical data helps identify trends and optimize maintenance intervals.

- Performance Trending: Track key performance indicators like operating pressures, temperatures, and cycle times. Gradual changes in these parameters often provide early warning of developing problems.

- Parts Inventory Management: Maintain adequate spare parts inventory based on lead times and failure history. Critical spare parts might include pump repair kits, common seal sizes, and filter elements.

Working with Qualified Technicians

- Training and Certification: Ensure maintenance personnel receive proper training on hydraulic system principles, safety procedures, and troubleshooting techniques. Consider certification programs offered by hydraulic equipment manufacturers and industry associations.

- Specialized Repair Services: For major component overhauls and complex troubleshooting that exceed your team’s capabilities, partner with experienced hydraulic repair specialists. At DuraFilter, we provide comprehensive repair services for all types of pumps, motors, and accumulators, with over 30 years of expertise serving the North American hydraulic industry.

Attempting complex repairs without proper expertise can cause additional damage and void warranties, making professional repair services a wise investment for critical components. - Emergency Response Planning: Establish procedures for emergency hydraulic system failures, including contact information for after-hours repair services, expedited parts suppliers, and temporary equipment rentals.

Safety Protocols During Hydraulic System Maintenance

Safety must be the top priority during all hydraulic system maintenance activities. Hydraulic fluid under pressure can cause serious injuries, including high-pressure injection injuries that may not be immediately apparent but can cause permanent damage.

- Lockout/Tagout Procedures: Always follow proper LOTO procedures before beginning maintenance work. Depressurize systems completely and use blocking to prevent accidental movement of hydraulic actuators.

- Personal Protective Equipment: Wear appropriate PPE including safety glasses, gloves, and protective clothing. Use face shields when working with pressurized systems or during system startup after maintenance.

- Pressure Relief: Never assume a system is depressurized. Use proper pressure relief procedures and verify zero energy state before beginning work. Accumulators can maintain pressure even when pumps are shut down.

- Fluid Handling: Use proper procedures for handling hydraulic fluid, including spill containment and disposal. Many hydraulic fluids are hazardous materials that require special handling and disposal procedures.

Common Hydraulic System Maintenance Mistakes to Avoid

Learning from common mistakes can save you time, money, and safety hazards. These frequent errors can undermine even the best-intentioned maintenance programs.

- Ignoring Small Leaks: Minor external leaks often indicate more serious internal problems. What appears to be a small nuisance leak might be the symptom of worn seals, excessive pressure, or contamination damage. Address all leaks promptly to prevent escalation.

- Reusing Contaminated Fluid: Never reuse hydraulic fluid without proper testing and reconditioning. Contaminated fluid will quickly damage clean components and negate the benefits of your maintenance work. When in doubt, use fresh fluid.

- Mixing Fluid Types: Using incompatible hydraulic fluids can cause seal swelling, additive precipitation, and system damage. Always verify fluid compatibility before mixing different brands or types, and maintain detailed records of fluid specifications.

- Overlooking Environmental Factors: Operating conditions significantly impact maintenance requirements. Dusty environments require more frequent filter changes, while high-temperature applications demand enhanced cooling system maintenance and more frequent fluid analysis.

- Skipping System Diagnostics: Modern diagnostic tools can identify developing problems before they cause failures. Invest in basic diagnostic equipment like flow meters, pressure gauges, and contamination monitors to support your hydraulic system preventive maintenance program.

- Inadequate Flushing During Repairs: When replacing major components, proper system flushing removes contamination and wear particles that could damage new parts. Follow manufacturer flushing procedures and use appropriate filtration during the flushing process.

Advanced Maintenance Technologies and Techniques

- Condition Monitoring Systems: Consider installing automated monitoring systems that track key parameters continuously. These systems can alert maintenance personnel to developing problems and provide trending data for optimization.

- Fluid Conditioning Systems: Kidney loop filtration systems and vacuum dehydration equipment can maintain fluid quality between scheduled changes, extending fluid life and improving system reliability.

- Predictive Maintenance Tools: Vibration analysis, thermography, and oil analysis can detect problems before they cause failures. These technologies complement traditional preventive maintenance and help optimize maintenance intervals.

Calculating the Return on Investment

Implementing an extensive hydraulic system maintenance program requires investment, but the returns are substantial and measurable. Consider these financial benefits when evaluating your maintenance strategy:

- Direct Cost Savings: Reduced repair costs, longer component life, and decreased downtime directly impact your bottom line. Companies typically see 300-400% return on preventive maintenance investments within the first year.

- Indirect Benefits: Improved safety, better product quality, and enhanced customer satisfaction provide additional value that’s harder to quantify but equally important for long-term success.

- Energy Savings: Well-maintained hydraulic systems consume less energy, providing ongoing operational savings that compound over time.

Partnering with Hydraulic System Experts

While internal maintenance capabilities are important, partnering with experienced hydraulic specialists can significantly enhance your maintenance program’s effectiveness. Look for partners who offer:

- Technical Expertise: Deep knowledge of hydraulic system design, troubleshooting, and repair across multiple equipment brands and applications.

- Quality Components: Access to OEM-quality parts and components from reputable manufacturers ensures compatibility and reliability.

- Emergency Support: 24/7 availability for critical failures and expedited repair services when downtime costs are high.

- Training and Support: Educational resources and training programs that help your team develop hydraulic system maintenance skills.

Conclusion: Your Path to Hydraulic System Reliability

Effective hydraulic system maintenance is both an art and a science. The principles outlined in this guide provide a solid foundation for developing a maintenance program that protects your investment, ensures safe operation, and maximizes equipment reliability. Remember that hydraulic system preventive maintenance is not just about following schedules. It’s about understanding your equipment, monitoring performance trends, and making informed decisions based on data and experience.

The key to success lies in consistency, attention to detail, and continuous improvement. Start with the basics: clean fluid, proper filtration, and regular inspections. Build your program gradually, adding advanced monitoring and diagnostic capabilities as your team’s expertise grows.

Every hour invested in proper servicing hydraulics pays dividends in reduced downtime, lower repair costs, and improved safety. Your hydraulic systems are critical assets that deserve the attention and care as outlined.

At DuraFilter, we understand the challenges of maintaining complex hydraulic systems in demanding industrial environments. Whether you need quality replacement components, technical consultation, or emergency repair services, we’re here to help you achieve maximum uptime and performance from your hydraulic investments.

Don’t wait for a costly breakdown to highlight the importance of proper hydraulic system maintenance. Contact DuraFilter today to discuss how our expertise and quality components can support your maintenance objectives and keep your operations running smoothly.

FAQs :

1. Why is hydraulic system maintenance important?

Hydraulic system maintenance is important because it prevents unexpected breakdowns, reduces wear on pumps and valves, and keeps the system running at proper pressure. Regular maintenance also extends equipment life and helps avoid costly repairs or downtime.

2. What are the basic steps in hydraulic maintenance?

Basic hydraulic maintenance includes checking fluid levels, replacing filters, and inspecting hoses, seals, and fittings for leaks. You should also monitor system pressure, clean contamination points and ensure the hydraulic fluid is clean and at the correct viscosity for proper operation.

3. What is the main cause of hydraulic system downtime?

The biggest cause of hydraulic downtime is contamination in the fluid-dirt, water or metal particles that damage pumps, valves, and seals. Contaminated fluid leads to overheating, pressure loss, and premature component failure, resulting in unexpected system shutdowns.

4. How do I maintain a high-pressure hydraulic system?

To maintain a high-pressure hydraulic system, regularly inspect hoses, fittings, and seals for leaks, monitor system pressure, and replace filters on time. Keeping the fluid clean and following a preventive maintenance schedule ensures safe and efficient operation.

5. How can I prevent costly hydraulic repairs?

Prevent costly hydraulic repairs by performing regular maintenance, keeping fluids clean, checking for leaks, and replacing worn components on time. Early detection of issues prevents major breakdowns and extends system life.