Types of Hydraulic Accumulators Offered by DURAfilter

Our collection features the following types of hydraulic accumulators:

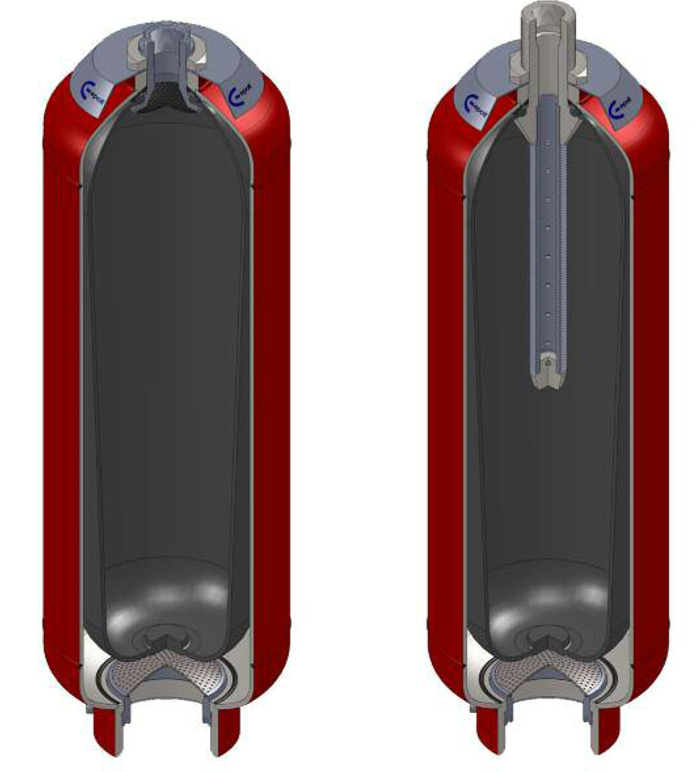

- Bladder Accumulators: Bladder accumulators feature a flexible bladder separating gas and fluid chambers. They provide rapid response and are ideal for applications requiring frequent pressure changes, such as hydraulic presses, injection molding machines and mobile machinery. The bladder design prevents gas and fluid mixing, ensuring system cleanliness and minimizing contamination risks. Their ability to stabilize hydraulic accumulator pressure makes them highly efficient for dynamic operations.

- Piston Accumulators: Piston accumulators use a spring-loaded sliding piston to separate gas and fluid. Known for their durability, they can handle high pressure and large fluid volumes, making them suitable for use in heavy industrial machinery, steel mills, and offshore drilling equipment. The sliding piston provides precise pressure control and can accommodate extreme operating conditions, including wide temperature ranges and high-vibration environments.

- Diaphragm Accumulators: Compact and lightweight, diaphragm accumulators are perfect for low-volume, high-frequency operations. They are commonly used as low-pressure hydraulic accumulators in compact hydraulic systems or mobile equipment. Their simple construction reduces maintenance requirements while maintaining reliable performance.

Working Principle of Hydraulic Accumulator

A hydraulic accumulator contains a piston or a membrane that compresses and confines an inert gas like nitrogen. There is a hydraulic fluid on the other end of the membrane. When system pressure rises, the gas compresses, storing energy; when pressure drops, the gas expands, pushing fluid back into the system. This ensures the stability of hydraulic accumulator pressure, supporting consistent performance and preventing component wear.

Effective pressure control through an accumulator in a hydraulic system enhances energy efficiency, reduces pump stress, and absorbs shocks resulting from rapid load changes. Both high-pressure and low-pressure hydraulic accumulators enhance system safety and reliability.

With proper pressure control, hydraulic accumulators extend the life of pumps, valves, and other critical hydraulic components by preventing over-pressurization and reducing the likelihood of damage.

Key Benefits of Hydraulic Accumulators

At DURAfilter, our hydraulic accumulators deliver substantial value across various industries. Here are the unique benefits that set our accumulators apart:

- Enhanced Energy Storage and Release: Our hydraulic accumulators, whether bladder, piston, or diaphragm types, offer highly efficient energy storage. By storing energy and releasing it when necessary, accumulators reduce the workload on pumps and compressors, resulting in improved fuel efficiency and lower energy consumption.

- Protection Against System Failures: Our hydraulic accumulators can buffer pressure spikes and fluid losses, which minimizes the risk of system failures and unplanned downtime. This helps maintain uninterrupted operations, reducing the risk of unexpected downtime, and extending the lifespan of critical system components.

- Pressure Stabilization: These devices ensure that pressure fluctuations within the system are absorbed and mitigated, leading to smoother operation and fewer equipment failures. Whether used in mobile machinery or industrial equipment, they ensure smoother operations and help prevent wear on sensitive components, enhancing the overall efficiency of your hydraulic system.

- Safety: Hydraulic shocks and over-pressurization cause risks to machinery and personnel. Our accumulators are designed to manage pressure spikes caused by sudden valve closures, cylinder reversals, or external impacts and enhance the safety of the entire hydraulic system. By doing this, they help prevent potential damage to machinery and personnel.

- Volume Compensation: Accommodates fluid volume changes due to temperature fluctuations without pressure variations.

- Emergency Power: Provides auxiliary hydraulic power during electrical failures or pump malfunctions for controlled system shutdown.

- Leakage Compensation: Maintains pressure in hydraulic circuits with minor internal leakage between maintenance intervals.

Why Hydraulic Systems Need Accumulators

Modern hydraulic systems demand precise pressure control, energy efficiency, and component protection that pumps alone cannot provide. Hydraulic accumulators address several critical system limitations. Pumps deliver constant flow regardless of demand, causing excess energy conversion to heat during low-demand periods. Accumulators capture this surplus energy, reducing electrical consumption by 20-50% in cycling applications. Sudden load changes create pressure transients exceeding 3,000 PSI in milliseconds, sufficient to damage seals, burst hoses, and fracture metal components.

Hyd accumulators absorb these shocks instantaneously, extending component life by preventing fatigue failures. In mobile equipment, accumulators enable regenerative braking, converting kinetic energy back into hydraulic pressure for reuse. Emergency shutdown procedures require controlled valve actuation and cylinder retraction even when primary power fails, only possible with stored hydraulic energy.

Without accumulators, systems require oversized pumps, frequent component replacement, higher energy consumption, and increased downtime, significantly impacting operational economics and equipment reliability.

Applications of Hydraulic Accumulators

Our hydraulic accumulators are widely utilized across the following industries:

- Heavy Machinery: In equipment such as excavators and cranes, our accumulators help absorb shock loads and stabilize pressure, enhancing performance and longevity.

- Industrial Systems: Hydraulic presses and manufacturing systems use DURAfilter accumulators to maintain consistent pressure, improving efficiency and product quality.

- Mobile Equipment: In vehicles such as forklifts and agricultural machinery, our accumulators ensure stable operation and energy efficiency.

- Energy Systems: Our accumulators deliver emergency power and ensure pressure compensation and fluid balancing in energy systems.

Tips to Choose the Right Hydraulic Accumulator for Your Application

The following tips will help you choose the right hydraulic accumulator for your application:

- Address Your System’s Purpose: Determine what you need the accumulator in hydraulic system to do: energy storage, pressure maintenance, volume compensation or shock absorption. Each application requires different accumulator sizing and performance.

- Know Your Operating Pressure: What is the maximum and minimum working pressure of your system? High-pressure hydraulic accumulators are ideal for heavy-duty or industrial systems, while low-pressure hydraulic accumulators suit lubrication or thermal compensation applications.

- Evaluate Energy and Volume Requirements: Calculate the energy to be stored and the fluid volume to be replaced. This helps in choosing the correct accumulator size and pre-charge pressure.

- Choose the Right Accumulator Size: This requires a comprehensive consideration of the application requirements. For instance:

- Bladder accumulators ensure a quick response, making them ideal for dynamic systems.

- Piston accumulators are durable and versatile, capable of handling high volumes and pressures.

- Diaphragm accumulators are compact, lightweight, and suited for small systems. They are ideal for applications where special mounting orientation is required due to compact spaces.

- Match Temperature and Fluid Compatibility: Ensure the accumulator’s materials, such as bladder, seals, and body, are compatible with your system fluid and temperature range to avoid premature wear or leakage.

- Check for Certification and Quality Standards: Always select accumulators that meet international standards, such as PED, CE, or ASME. DURAfilter’ s OEM brands like EPE and Roth Hydraulics ensure top-tier quality and compliance.

- Seek Expert Guidance: We help our customers to choose the correct hydraulic accumulator based on pressure range, application type, and environmental factors.

DURAfilter offers comprehensive selection of high-pressure hydraulic accumulators, low-pressure hydraulic accumulators and OEM replacement solutions from industry-leading manufacturers. Explore our complete range of bladder, piston, and diaphragm accumulators engineered for durability, safety compliance, and demanding operational environments.

Contact our technical team today for expert guidance in selecting the right accumulator in hydraulic system for your specific requirements delivering industry-ready performance backed by 30+ years of hydraulic expertise.

FAQs

Q. What is the difference between high-pressure and low-pressure accumulators?

Ans. High-pressure hydraulic accumulators are designed for systems above 700-1000 PSI and low-pressure hydraulic accumulators for systems below 150-225 PSI. High-pressure accumulators can withstand and manage higher pressures, such as energy storage in hydraulic systems and low-pressure accumulators are used in applications requiring less force.

Q. How often should hydraulic accumulators be serviced or replaced?

Ans. These systems can perform for 10-12 years with proper maintenance. Regular inspection of pre-charge pressure, seals, and safety valves ensures the reliable operation of hydraulic accumulators. Components like seals should be replaced every two to three years if the systems are used in challenging conditions. The shell of an accumulator must be hydrotested every five years and replaced if necessary. DURAfilter provides guidance and OEM replacements to maintain system efficiency.

Q. Are hydraulic accumulators high maintenance?

Ans. Hydraulic accumulators are relatively low-maintenance components when properly installed and operated within design parameters. Routine maintenance consists primarily of quarterly pre-charge pressure verification, a simple 10-minute procedure requiring isolation, depressurization, and nitrogen pressure measurement. Compared to pumps, valves, and cylinders, hyd accumulators require significantly less attention, making them among the most reliable hydraulic components.

DURAfilter recommends establishing preventive maintenance schedules based on OEM guidelines and operating conditions to maximize accumulator life and system reliability while minimizing unexpected failures and costly downtime.

Q. How can I tell if my accumulator needs replacement?

Ans. Your accumulator may need replacement if you observe signs, including loss of pressure, slow system response, gas leakage, or reduced fluid capacity. DURAfilter offers OEM replacement accumulators for all major brands.

Q. What factors affect hydraulic accumulator pressure?

Ans. The hydraulic accumulator pressure depends on the gas pre-charge, system load, and operating temperature. Maintaining the correct pre-charge pressure is crucial for consistent performance and longer accumulator life.

Q. Can a hydraulic accumulator be used as an emergency power source?

Ans. A high-pressure hydraulic accumulator can store enough energy to perform essential operations or safety functions during power loss, ensuring uninterrupted hydraulic system control.

Q. How often should I check or recharge the accumulator pre-charge?

Ans. Inspect the hydraulic accumulator pressure every 6 to 12 months, or as recommended by the manufacturer. Low pre-charge can reduce efficiency and cause premature wear.

Q. What happens if the hydraulic accumulator is overcharged?

Ans. Overcharging increases system pressure, potentially damaging seals or reducing the accumulator’s effective volume. Always follow OEM guidelines for safe pre-charge levels.