Hydraulic systems power some of the most critical equipment across industries, from construction machinery to manufacturing plants. At the heart of keeping these systems running smoothly is proper hydraulic filter maintenance. After more than 30 years serving the North American hydraulic industry, we’ve seen firsthand how proactive filter care prevents costly breakdowns and extends equipment lifespan.

In this comprehensive guide, we’ll share practical hydraulic filter maintenance strategies based on real-world experience, helping you optimize performance while avoiding common pitfalls that lead to system failures.

Why Hydraulic Filter Maintenance is Essential

Hydraulic filters serve as your system’s first line of defense against contamination. These components remove particles, debris, and contaminants from hydraulic fluid before they can damage pumps, valves, cylinders, and motors. Without regular maintenance, even microscopic particles accumulate and cause:

- Accelerated component wear that shortens equipment life by up to 50%

- Reduced system efficiency leading to higher energy costs

- Unexpected downtime that disrupts production schedules

- Expensive repairs that could have been prevented with routine care

According to industry research, approximately 75% of hydraulic system failures stem from fluid contamination making filter maintenance one of the most cost-effective investments you can make.

Understanding Your Hydraulic Filter System

Before diving into maintenance procedures, it’s essential to understand the different filter types in your system:

- Suction Filters: Located before the pump, these protect the pump from large contaminants in the reservoir. They typically feature coarser filtration ratings.

- Pressure Filters: Positioned after the pump in high-pressure lines, these filters protect sensitive components like servo valves and proportional valves with fine filtration.

- Return Line Filters: Installed before fluid returns to the reservoir, these capture wear particles and contaminants generated during system operation.

- Off-Line Filtration: Operates independently from the main system, continuously cleaning fluid in the reservoir through a dedicated pump and filter circuit.

Each filter type requires specific maintenance attention based on its location and function within your hydraulic system.

Essential Hydraulic Filter Maintenance Schedule

Establishing a structured maintenance schedule is critical for reliability. Here’s what we recommend based on typical industrial applications:

Daily Checks

- Visually inspect filters for leaks or physical damage

- Check filter housing for unusual heat buildup

- Monitor system pressure gauges for abnormal readings

- Look for signs of fluid contamination in sight glasses

Weekly Inspections

- Review bypass indicator lights or gauges

- Check differential pressure across filters

- Inspect filter housings for proper sealing

- Document any pressure variations

Monthly Maintenance

- Test hydraulic fluid for contamination levels

- Analyze filter differential pressure trends

- Inspect filter elements for damage or saturation

- Check O-rings and seals for deterioration

Quarterly Service

- Replace filter elements according to manufacturer specifications

- Conduct thorough fluid analysis testing

- Inspect internal housing components

- Clean reservoir and breathers

Oil Filter Maintenance: Critical Steps for System Health

While hydraulic filter maintenance focuses on the broader system, oil filter maintenance specifically addresses the hydraulic fluid’s cleanliness. These practices work hand-in-hand to ensure optimal performance:

- Monitor Fluid Condition Regularly

Clean hydraulic oil is essential for system longevity. Implement these oil filter maintenance practices:

- Visual Assessment: Check oil color and clarity. Healthy hydraulic fluid should be clear or amber. Dark, cloudy, or milky fluid indicates contamination, oxidation, or water intrusion.

- Fluid Sampling: Take samples from consistent locations at operating temperature. This provides accurate trending data over time.

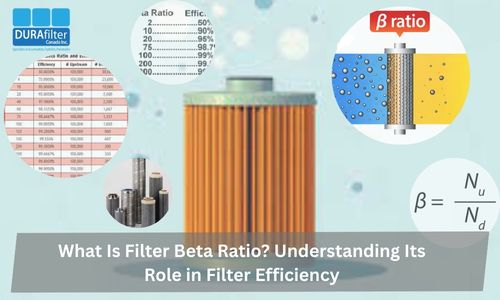

- Laboratory Analysis: Professional fluid analysis reveals particle counts, viscosity changes, additive depletion, and water content that aren’t visible to the naked eye.

- Change Oil Filters at Proper Intervals

Don’t wait for filter bypass indicators before changing oil filters. Consider these factors when determining replacement intervals:

- Operating hours and duty cycles

- Environmental conditions and contamination exposure

- System pressures and temperatures

- Manufacturer recommendations

- Fluid analysis results

As a general guideline, change oil filters every 1,000-2,000 operating hours in normal conditions, or more frequently in harsh environments.

- Use Quality Replacement Filters

Not all replacement filters are created equal. Low-quality aftermarket filters may fail to meet original specifications, leading to:

- Inadequate filtration that allows harmful particles through

- Premature element collapse under pressure

- Chemical incompatibility with hydraulic fluids

- Improper bypass valve settings

At DURAfilter, we supply OEM-grade filter elements from trusted European manufacturers, ensuring reliable performance and proper system protection.

Step-by-Step Filter Replacement Procedure

Proper installation is just as important as using quality components. Follow these steps for effective hydraulic filter maintenance:

Step 1: Safety First

- Shut down and lock out the system

- Relieve all hydraulic pressure

- Allow components to cool to safe handling temperatures

- Wear appropriate personal protective equipment

Step 2: Prepare the Workspace

- Position drain pans to catch hydraulic fluid

- Clean the external filter housing thoroughly

- Have new filters, O-rings, and clean rags ready

- Verify you have the correct replacement elements

Step 3: Remove Old Filter

- Note the filter orientation for proper reinstallation

- Carefully remove the filter housing or spin-on element

- Inspect the removed filter for unusual wear patterns or contamination

- Check for metal particles indicating internal component damage

Step 4: Install New Filter

- Inspect the housing for damage or debris

- Replace all O-rings and seals

- Lubricate O-rings with clean hydraulic fluid

- Hand-tighten spin-on filters according to specifications

- For cartridge filters, ensure proper seating and torque specifications

Step 5: System Restart

- Check fluid levels and top off if necessary

- Start the system and monitor for leaks

- Verify proper pressure readings

- Check bypass indicators after initial startup

Common Hydraulic Filter Maintenance Mistakes to Avoid

Even experienced maintenance teams sometimes overlook critical details. Here are mistakes we frequently encounter:

- Ignoring Bypass Indicators: When filters become clogged, bypass valves open to protect the pump but this allows unfiltered fluid to circulate. Never ignore bypass warnings.

- Using Incorrect Filtration Ratings: Installing filters with improper micron ratings compromises system protection. Always match or exceed OEM specifications.

- Neglecting Breather Filters: Reservoir breathers prevent airborne contamination. Dirty breathers allow dust and moisture into your system.

- Mixing Hydraulic Fluids: Different fluid types and brands may not be compatible. Always use the manufacturer’s recommended fluid specification.

- Overlooking Temperature Effects: High operating temperatures accelerate fluid degradation and filter element failure. Address root causes of overheating.

Signs Your Hydraulic Filters Need Immediate Attention

Watch for these warning signs that indicate urgent hydraulic filter maintenance is required:

- Sluggish System Response: Slower actuator speeds or reduced force output may indicate restricted flow through clogged filters.

- Unusual Noise: Whining or cavitation sounds from the pump often result from restricted suction filters.

- Elevated Operating Temperatures: Increased system heat can indicate filter restriction forcing the relief valve to bypass.

- Frequent Bypass Activation: If bypass indicators trigger regularly, filters are undersized or maintenance intervals are too long.

- Erratic Operation: Inconsistent performance or pressure fluctuations often stem from contamination affecting control valves.

Optimizing Your Maintenance Program

Transform hydraulic filter maintenance from a reactive chore into a proactive strategy:

- Implement Condition-Based Monitoring: Use sensors and data analytics to schedule maintenance based on actual filter condition rather than arbitrary time intervals.

- Train Your Team: Ensure maintenance personnel understand proper procedures, safety protocols, and the importance of using quality components.

- Keep Detailed Records: Document filter changes, fluid analysis results, and system performance trends to identify patterns and optimize maintenance schedules.

- Partner with Experts: Work with experienced hydraulic specialists who can provide technical support, quality components, and application-specific recommendations.

- Consider Upgrades: If you’re experiencing chronic contamination issues, evaluate whether your current filtration system meets your application requirements. Upgrading to higher-quality filters or adding offline filtration can dramatically improve system cleanliness.

The DURAfilter Advantage

With over 30 years of experience in hydraulic components and systems, DURAfilter North America understands that proper filter maintenance is essential for equipment reliability. We provide:

Conclusion: Prevention Pays

Effective hydraulic filter maintenance and oil filter maintenance aren’t just about following schedules, they’re about protecting your investment in critical equipment. By implementing the strategies outlined in this guide, you’ll reduce downtime, extend component life, and avoid costly repairs.

The minimal time and cost invested in proactive filter maintenance delivers substantial returns through improved reliability, efficiency, and equipment longevity. Whether you operate construction equipment, manufacturing systems, or mobile hydraulics, clean hydraulic fluid filtered properly is the foundation of dependable performance.

Contact DURAfilter for expert guidance on hydraulic filter maintenance for your specific application. Our team is ready to help you optimize your maintenance program with quality components and technical expertise.