One of the most frequently asked questions in industrial maintenance circles is whether hydraulic fluid and hydraulic oil are the same thing. This confusion isn’t surprising, even experienced technicians sometimes use these terms interchangeably. However, understanding the real difference between hydraulic oil and fluid is crucial for optimal equipment performance, component longevity, and avoiding costly maintenance mistakes.

The stakes are higher than you might think. Using the wrong fluid type can lead to seal failure, reduced system efficiency, component damage, and even complete system breakdown. With hydraulic systems representing significant capital investments, often hundreds of thousands of dollars, making the right fluid choice isn’t just about technical correctness; it’s about protecting your bottom line.

We’ll explore the technical differences, application considerations, and practical implications that every maintenance professional, engineer, and equipment operator should understand to make informed decisions for their hydraulic systems.

Understanding Hydraulic Fluid: The Broader Category

To answer “is hydraulic oil the same as hydraulic fluid,” we first need to understand that hydraulic fluid is the broader category. Hydraulic fluid encompasses any liquid medium used to transmit power in hydraulic systems. This includes petroleum-based oils, water-based fluids, synthetic fluids, and specialized formulations designed for specific applications.

Hydraulic Fluid Composition and Types

The foundation of any hydraulic fluid is its base stock, which determines many of the fluid’s fundamental properties.

Petroleum-based hydraulic fluids, including mineral oil hydraulic fluid, represent the most common type used in industrial applications. These fluids start with refined crude oil that undergoes extensive processing to achieve the desired viscosity, thermal stability, and purity levels.

Water-based hydraulic fluids offer unique advantages in specific applications. These include water-glycol mixtures, water-oil emulsions, and high-water-content fluids. While less common than petroleum-based options, water-based fluids provide excellent fire resistance and environmental safety in applications where these characteristics outweigh their limitations.

Synthetic hydraulic fluids represent the premium category, engineered to deliver superior performance under extreme conditions. These include phosphate esters, polyalphaolefins (PAO), and other chemically engineered base stocks. Synthetic fluids typically offer extended temperature ranges, better thermal stability, and longer service life than conventional petroleum-based alternatives.

Additives: The Performance Enhancers

Modern hydraulic fluids contain sophisticated additive packages that significantly impact performance and longevity. Anti-wear additives, typically zinc dialkyl dithiophosphate (ZDDP), form protective films on metal surfaces to prevent wear under boundary lubrication conditions. Antioxidants prevent fluid degradation by neutralizing free radicals that accelerate oxidation processes.

Hydraulic Oil: The Petroleum-Based Subset

When we examine the difference between hydraulic oil and fluid, hydraulic oil specifically refers to petroleum-based hydraulic fluids. This distinction is important because it helps clarify usage contexts and technical specifications. Hydraulic oil, as a subset of hydraulic fluids, shares the same basic function but has specific characteristics derived from its petroleum base.

Mineral Oil Hydraulic Fluid Characteristics

Mineral oil hydraulic fluid, the most common type of hydraulic oil, offers several advantages that explain its widespread use. These fluids provide excellent lubrication properties, good thermal stability within normal operating ranges, and compatibility with standard seal materials. The viscosity characteristics of mineral oil hydraulic fluid make it suitable for most industrial hydraulic applications.

The refining process for hydraulic oils involves multiple steps to achieve the desired properties. The resulting mineral oil hydraulic fluid provides a cost-effective solution that meets the performance requirements of most hydraulic systems.

Hydraulic Fluid vs Hydraulic Oil: The Key Differences

Understanding the hydraulic fluid vs hydraulic oil distinction requires examining several critical factors that influence performance, application suitability, and cost considerations.

Base Material and Composition Differences

The fundamental difference between hydraulic oil and fluid lies in the base material composition. Hydraulic oil specifically uses petroleum-based base stocks, while hydraulic fluid encompasses petroleum, synthetic, and water-based options. This distinction affects everything from operating temperature ranges to environmental impact and disposal requirements.

Synthetic hydraulic fluids offer superior thermal stability, often maintaining consistent properties at temperatures where petroleum-based hydraulic oils would degrade. However, this performance advantage comes with significantly higher initial costs and potential compatibility issues with existing system components.

Lubrication Properties and Performance

The lubrication characteristics represent another key area where the difference between hydraulic oil and fluid becomes apparent. Mineral oil hydraulic fluid provides excellent boundary lubrication properties due to its natural hydrocarbon structure and compatibility with traditional anti-wear additives.

Synthetic hydraulic fluids often deliver superior lubrication performance, particularly under extreme pressure and temperature conditions. However, this enhanced performance requires careful attention to additive compatibility and potential seal swelling issues during conversion from petroleum-based systems.

Application-Specific Considerations

Different industries and applications favor specific fluid types based on performance requirements, safety considerations, and environmental factors. Mobile hydraulic equipment typically uses petroleum-based hydraulic oils due to their cost-effectiveness and wide temperature operating ranges.

Industrial manufacturing often employs mineral oil hydraulic fluid for general applications, with synthetic alternatives reserved for high-temperature processes or critical equipment where extended fluid life justifies the higher initial cost. For systems requiring premium filtration to maintain fluid quality, high-quality filter elements become crucial for protecting your hydraulic fluid investment.

Environmental Impact and Sustainability

The environmental impact represents an increasingly important factor in the hydraulic fluid vs hydraulic oil decision. Petroleum-based hydraulic oils, while effective and economical, present environmental concerns related to biodegradability and toxicity.

Biodegradable hydraulic fluids, including vegetable oil-based and synthetic biodegradable options, offer reduced environmental impact but may require more frequent replacement and careful compatibility assessment with existing system components.

The disposal requirements for different fluid types vary significantly, with some synthetic fluids requiring specialized disposal procedures while biodegradable options may be processed through standard waste management channels.

Making the Right Choice: When to Use Which

Selecting between different hydraulic fluid types requires careful consideration of multiple factors that impact both immediate performance and long-term operating costs.

- Equipment and Application Assessment: The first step in determining whether hydraulic oil or alternative hydraulic fluids are appropriate involves thorough assessment of equipment requirements. OEM recommendations provide the starting point, but operating conditions often require modifications to standard specifications.

High-pressure systems typically benefit from synthetic hydraulic fluids that maintain viscosity and lubrication properties under extreme conditions. Conversely, standard industrial applications often perform adequately with mineral oil hydraulic fluid, making the cost-performance optimization favor petroleum-based options. - Temperature Range Considerations: Operating temperature ranges significantly influence the fluid selection decision. Standard mineral oil hydraulic fluid typically performs well within -20°F to 180°F (-29°C to 82°C) ranges, covering most industrial applications.

Extended temperature applications require careful fluid selection. Cold weather operation may necessitate synthetic hydraulic fluids with superior low-temperature flow characteristics, while high-temperature applications benefit from synthetic options with enhanced thermal stability.

Consequences of Using the Wrong Fluid Type

Understanding what happens when you make the wrong choice helps emphasize the importance of proper selection.

Performance Degradation Issues

- Using incompatible hydraulic fluids can cause immediate and long-term performance problems. Mixing different fluid types, particularly petroleum and synthetic bases, can cause additive precipitation, seal swelling, and reduced lubrication effectiveness.

- Temperature-related performance issues occur when fluid selection doesn’t match operating conditions. Using standard mineral oil hydraulic fluid in high-temperature applications leads to accelerated fluid breakdown, increased maintenance requirements, and potential component damage.

- Viscosity-related problems arise when fluid selection doesn’t match system design parameters. Too-heavy fluids cause sluggish operation and increased power consumption, while too-light fluids provide inadequate lubrication and component protection.

Component Wear and Damage

- The wrong fluid choice accelerates component wear through multiple mechanisms. Inadequate lubrication properties lead to increased friction, heat generation, and premature component failure. This is particularly problematic in high-pressure applications where boundary lubrication conditions are common.

- Seal compatibility issues cause perhaps the most expensive damage. Using hydraulic fluids incompatible with system seals leads to seal swelling, hardening, or degradation. The resulting leakage not only wastes fluid but can cause safety hazards and environmental contamination.

- Pump wear represents another critical concern. Hydraulic pumps operating with inappropriate fluids experience accelerated wear of precision surfaces, leading to internal leakage, reduced efficiency, and eventual failure requiring expensive hydraulic pump repair services.

Maintenance and Filtration Requirements

Different hydraulic fluid types require specific approaches to maintain optimal performance and protect your system investment.

Filtration System Design Considerations

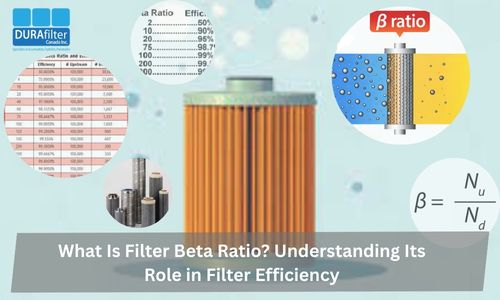

Different hydraulic fluid types require different filtration strategies to maintain cleanliness standards. Mineral oil hydraulic fluid typically performs well with standard cellulose or synthetic filter media, while water-based hydraulic fluids may require specialized filter media to prevent bacterial growth and maintain fluid stability.

The ISO 4406 cleanliness standard provides a framework for establishing filtration requirements, but the specific targets vary based on fluid type and system sensitivity. High-performance synthetic hydraulic fluids often justify more aggressive filtration to protect the investment in premium fluids and extend service intervals.

Fluid Condition Monitoring Programs

Effective condition monitoring programs must account for the specific characteristics of different hydraulic fluid types. Mineral oil hydraulic fluid monitoring typically focuses on oxidation, contamination, and additive depletion, while synthetic fluids may require different analytical approaches.

Trending analysis becomes particularly important with premium hydraulic fluids where extended service intervals make early detection of problems crucial for preventing expensive component damage.

Contamination Control Strategies

Water contamination affects different hydraulic fluid types differently, requiring specific control strategies. Particle contamination control requirements vary based on fluid type and system sensitivity. High-performance synthetic hydraulic fluids operating in precision systems may require more aggressive contamination control than standard industrial applications.

Industry-Specific Fluid Selection Guidelines

Different industries have developed preferences for specific hydraulic fluid types based on performance requirements, safety considerations, and economic factors.

Manufacturing and Industrial Applications

General manufacturing applications typically favor mineral oil hydraulic fluid due to cost-effectiveness and adequate performance for most industrial hydraulic systems. The widespread availability, established service procedures, and extensive compatibility make petroleum-based hydraulic oils the default choice for many applications.

Precision manufacturing processes may justify synthetic hydraulic fluids where consistent viscosity and enhanced lubrication properties improve product quality and reduce maintenance requirements. The higher initial cost can be justified by improved system performance and extended maintenance intervals.

Mobile Equipment and Construction

Mobile hydraulic equipment typically operates under more demanding conditions than stationary industrial systems, often justifying higher-performance hydraulic fluids. Temperature variations, contamination exposure, and space limitations for maintenance favor synthetic hydraulic fluids in many mobile applications.

Construction equipment operating in extreme environments may require specialized hydraulic fluids with enhanced low-temperature performance or superior thermal stability. The cost of equipment downtime in remote locations often justifies the investment in premium hydraulic fluids.

Environmental and Regulatory Considerations

The fluid selection decision increasingly involves environmental and regulatory factors that impact choice beyond pure performance considerations.

- Environmental Impact Assessment: Biodegradability represents a key environmental consideration, with petroleum-based hydraulic oils generally providing inferior environmental performance compared to biodegradable alternatives. However, biodegradable hydraulic fluids may require more frequent replacement and specialized disposal procedures.

Carbon footprint analysis includes both the manufacturing impact of different hydraulic fluid types and the operational efficiency implications. Higher-performance synthetic hydraulic fluids may reduce overall environmental impact through improved system efficiency and extended service life. - Regulatory Compliance Requirements: Fire safety regulations in specific industries mandate fire-resistant hydraulic fluids, typically water-based or synthetic formulations. These requirements override performance and cost considerations in applications where fire hazards pose unacceptable risks.

Environmental discharge regulations affect fluid selection in marine, mining, and other applications where hydraulic fluid release could impact sensitive environments.

Economic Analysis: Total Cost of Ownership

Making informed decisions requires comprehensive economic analysis that considers all cost factors over the equipment lifecycle.

- Initial Cost vs. Long-term Value: While mineral oil hydraulic fluid typically costs significantly less initially than synthetic alternatives, the total cost analysis must include fluid change intervals, system downtime, and performance impacts. Synthetic hydraulic fluids costing 3-5 times more initially may provide 2-4 times longer service life, affecting the overall economic calculation.

Energy efficiency impacts affect operating costs through reduced power consumption with higher-performance hydraulic fluids. Systems using synthetic hydraulic fluids with superior viscosity characteristics often demonstrate 5-10% energy savings compared to standard options. - Maintenance Cost Considerations: Maintenance cost reductions include extended service intervals, reduced component wear, and fewer fluid-related failures. These savings often offset the higher initial cost of premium hydraulic fluids in critical applications.

Downtime cost avoidance represents the most significant economic factor in many applications, where hydraulic system failures can cost thousands of dollars per hour in lost production.

Quality Standards and Specifications

Understanding quality standards helps ensure appropriate hydraulic fluid selection and performance verification across different applications and industries.

Industry Standards and Classifications

The ISO 6743-4 classification system provides a framework for hydraulic fluid specification, with different categories corresponding to various performance levels and application requirements. This system helps ensure compatibility between equipment requirements and fluid specifications.

Equipment manufacturer specifications often exceed industry standards for specific applications, requiring careful attention to OEM requirements when selecting hydraulic fluids for warranty compliance and optimal performance.

Conclusion: Making the Informed Choice

The question “is hydraulic oil the same as hydraulic fluid” has a clear answer: hydraulic oil is a subset of hydraulic fluids, specifically referring to petroleum-based options. Understanding this distinction, along with the broader implications, enables informed decisions that optimize system performance, minimize costs, and ensure regulatory compliance.

The choice between mineral oil hydraulic fluid and synthetic alternatives depends on multiple factors including operating conditions, performance requirements, environmental considerations, and economic analysis. While petroleum-based hydraulic oils remain the most common choice for general industrial applications, synthetic and specialty hydraulic fluids offer advantages that justify their higher costs in demanding applications.

Key decision factors include operating conditions, performance requirements, environmental factors, and comprehensive economic analysis. The hydraulic fluid vs hydraulic oil decision ultimately requires balancing these factors while considering the specific requirements of your application.

Working with Hydraulic Experts

Given the complexity of hydraulic fluid selection and the significant implications of making the wrong choice, partnering with experienced hydraulic specialists provides valuable support for critical decisions. Expert guidance helps navigate the technical specifications, compatibility requirements, and economic considerations that influence optimal fluid selection.

At DuraFilter, our three decades of experience in hydraulic systems provides deep understanding of how different hydraulic fluids perform in real-world applications. We work with leading manufacturers and provide comprehensive hydraulic system components and services to ensure our customers have access to the right solutions for their specific requirements.

Contact DuraFilter today to discuss your hydraulic fluid requirements and benefit from our extensive experience in hydraulic system optimization. Whether you’re evaluating fluid options for new equipment, considering conversion to higher-performance alternatives, or troubleshooting fluid-related problems, our expertise helps ensure you make the right choice for your specific application and operating requirements.

FAQs :

1. What is the difference between hydraulic fluid and hydraulic oil?

Hydraulic oil is a mineral-oil–based fluid mainly used for lubrication and power transfer, while hydraulic fluid can include water-based or synthetic options for fire resistance or environmental safety. The choice depends on the system’s operating conditions and performance needs.

2. What is meant by hydraulic fluid?

Hydraulic fluid is the liquid used in hydraulic systems to transmit power, lubricate components, and control temperature. It can be oil-based, synthetic, or water-based depending on the application and system requirements.

3. What is hydraulic oil used for?

Hydraulic oil is used to transmit power, lubricate moving parts, reduce friction, and protect components in hydraulic systems. It helps operate machinery like excavators, presses, forklifts, and industrial equipment smoothly and efficiently.

4. Is hydraulic fluid and hydraulic oil the same?

No, they’re not exactly the same. Hydraulic oil is a type of hydraulic fluid made from mineral oil, while “hydraulic fluid” includes oil-based, synthetic, and water-based fluids. Hydraulic fluids are chosen based on temperature, safety, and system requirements.

5. When should I use hydraulic fluid instead of hydraulic oil?

You should use hydraulic fluid instead of hydraulic oil when your system requires fire resistance, operates at extreme temperatures, or needs compatibility with specific seals and materials. Water-based or synthetic fluids are often preferred in high-heat, environmentally sensitive, or specialized industrial applications.